SUPPLIER Control PROCEDURE中英文.docx

SUPPLIER Control PROCEDURE中英文.docx

- 文档编号:4877795

- 上传时间:2022-12-11

- 格式:DOCX

- 页数:38

- 大小:93.74KB

SUPPLIER Control PROCEDURE中英文.docx

《SUPPLIER Control PROCEDURE中英文.docx》由会员分享,可在线阅读,更多相关《SUPPLIER Control PROCEDURE中英文.docx(38页珍藏版)》请在冰豆网上搜索。

SUPPLIERControlPROCEDURE中英文

SUPPLIERControlPROCEDURE

供应商控制程序

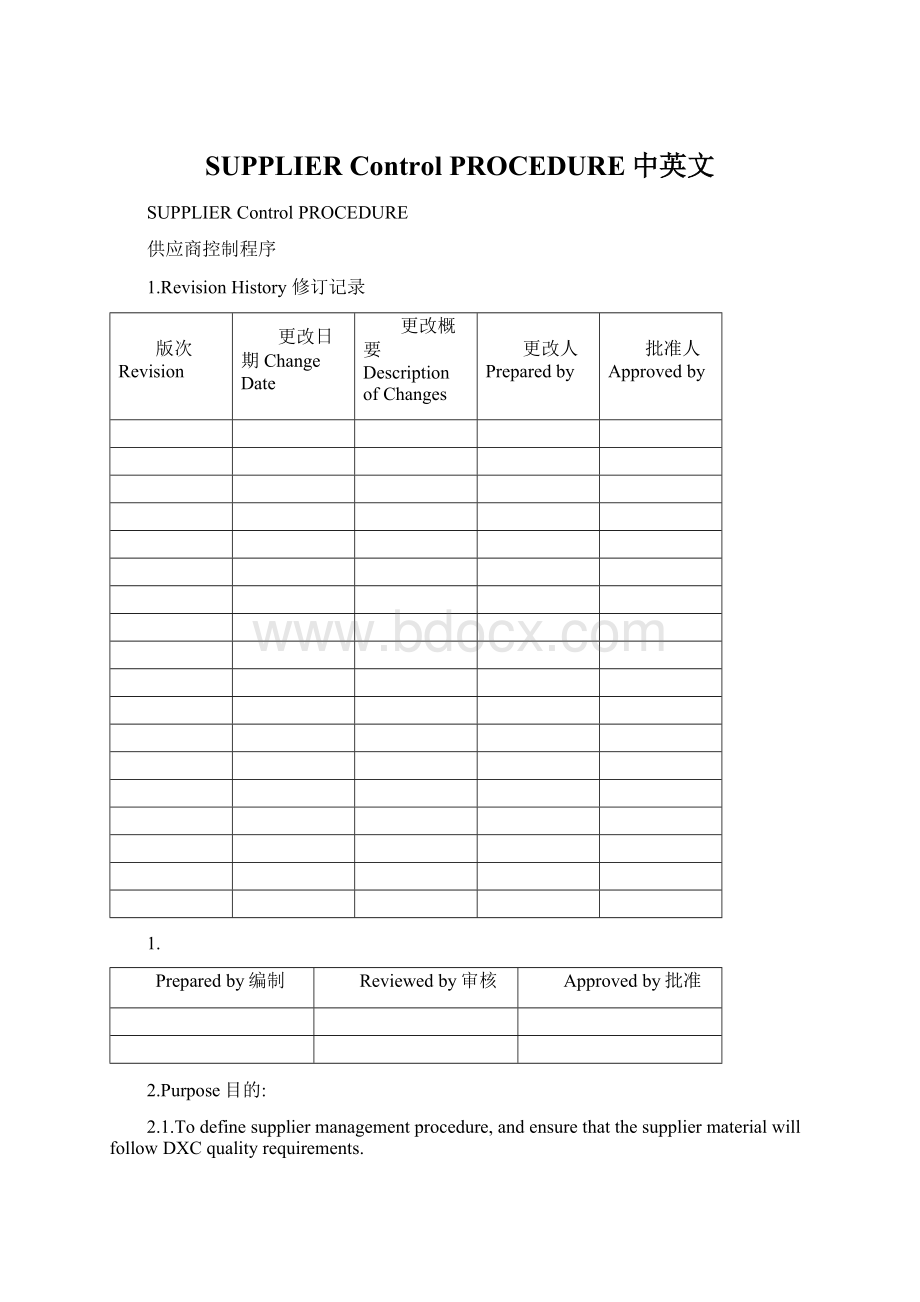

1.RevisionHistory修订记录

版次Revision

更改日期ChangeDate

更改概要DescriptionofChanges

更改人Preparedby

批准人Approvedby

1.

Preparedby编制

Reviewedby审核

Approvedby批准

2.Purpose目的:

2.1.Todefinesuppliermanagementprocedure,andensurethatthesuppliermaterialwillfollowDXCqualityrequirements.

确立供应商管理程序,确保供应商之产品能满足DXC公司品质要求。

3.Scope范围:

3.1.ThisprocedureappliestoallDXCsuppliers.

该程序适用于DXC公司所有供应商。

4.ReferenceDocument参考文件

4.1.QualityManual品质手册

4.2.PurchasingProcedure采购程序

4.3.IncomingQualityControlProcedure进料品质控制程序

4.4.IQCmonthlyreportIQC月报

4.5.SourcingProcedure.供应商开发程序

5.Definition定义

5.1.AVL–Approvedsupplierlist合格供应商清单

5.2.CPAR–Correctiveandpreventiveactionrequest.纠正与预防措施申请

5.3.P.O.–Purchaseorder.采购订单

6.Responsibility职责:

6.1.QADepartment品质部:

6.1.1.Responsiblefortheverificationofthesupplier’squalitymanagementsystem,imposedrequirementforthecorrectiveandpreventiveaction.负责确认供应商质量管理体系,纠正与预防措施的要求。

6.1.2.Responsibleforthedeterminationandverificationofthesupplier’squalityperformanceandthecooperationperformanceaccordingtotheCPARanswer.负责确认供应商的品质绩效并通过CPAR的回复情况评估和合作态度。

6.1.3.Responsibleforevaluation,auditandre-evaluationthesupplier’squalitymanagementsystem.负责评估、审核和二次评估供应商品质管理系统。

6.1.4.Responsibleforreportingtothesuppliers,purchasingdepartmentandsourcingdepartmentregardingtheinformationontherejectedproductsandthesupplier’squalityperformance.

负责向供应商、采购部、采购开发部门报告来料拒收信息和供应商品质状况。

6.2.SourcingDepartment采购开发部:

6.2.1.Responsibleforthedeterminationandverificationofthecompetitivepricing.负责决定和确认有竞争力的价格。

6.2.2.ResponsibletosearchfortheprospectivesupplieroftheproductthatDXCrequires.负责寻找符合DXC公司产品要求的后备供应商。

6.2.3.Prepareandupdatetheapprovalsupplierlist.

准备和更新合格供应商清单。

6.2.4.ContinualmonitoringtherelationshipbetweenDXCandsupplier.

持续跟进DXC公司和供应商之间的关系。

6.3.PurchasingDepartment采购部

6.3.1.ResponsiblefortheselectionandapprovaloftheP.O.basedontheAVL.负责在合格供应商中选择供应商并批准采购订单。

6.3.2.ResponsibletopurchaseproductsonlyfromtheAVL.

负责仅向合格供应商清单中的供应商采购产品。

6.3.3.ResponsibleforthecommunicationbetweenDXCandthesupplier.

负责推动DXC和供应商之间的沟通。

6.3.4.ResponsibletofollowthematerialontimedeliveryaccordingtothePO.负责跟进供应商按PO规定的交期准时交货。

6.4.D&DDepartment开发部

6.4.1.Responsibletoevaluatethesupplier’ssamples.

负责评估供应商所提供的样品。

6.4.2.ResponsibletocheckthesuppliertechnologyandverifythatthesuppliercanmeetDXCrequirement.

负责检查供应商的工艺水平和确认供应商是否能满足DXC的产品要求。

6.5.Topmanagement高层管理

6.5.1.Responsibletoapprovalthenewsupplier,basedonthescoredresultsandthecommentsfromthesupplierauditteam.

负责根据供应商审核小组的评估结果及建议进行新供应商的批准。

7.Generalprocedure一般程序

7.1.Newsupplierdevelopment新供应商开发

7.1.1.Sourcingdepartmentneedresearchthepotentialsupplierthroughmaterialexhibition,internetorotherwaysandissuethesupplierdatasheet(Attachment8.2)tothenewsuppliertogetmoreinformation.Sourcingforsecondsourceneededforthefollowingconditions:

采购开发部门需要通过产品展销会、英特网等方式寻找潜在的供应商,并向其发出供应商资料调查表(附件8.2)以获得更多的信息,以下情况下需寻找后备供应商。

7.1.1.1.Majormaterialsuppliers(includingthematerialwiththelongdeliverytime).

主要原材料供应商(包括交货期较长的物料)

7.1.1.2.Thesupplierwithmorethan100deliverylotspermonth.

供应商每月交货批次超过100批

7.1.1.3.Thesupplierwithmonthlyqualityperformancebelongtotheworstfivesupplierscontinuefor3months.

过去3个月的品质绩效连续排名在倒数五名的供应商之列

7.1.1.4.ThecostofthesupplierishigherthanDXCexpectations.

供应商成本比DXC预期的高

7.1.2.Sourcingdepartmentissuethesupplierselfsurveyreport(Attachment8.3)andthematerialspecificationtothepotentialsupplierafterreviewthesupplierfeedbackofthesupplierdatasheet

采购开发部门在审阅了供应回复的供应商资料调查表后向预备供应商发出自我调查报告(附件8.3)和物料规格说明书。

7.2.Newsupplierevaluation新供应商评估

7.2.1.Sourcingdepartmentcommunicateswiththenewsuppliertoarrangetheevaluationonthesuppliersiteafterreceivedthefeedbackoftheselfsurveyreportfromthesupplierwiththescorenotlessthan60point,iftheresultoftheselfsurveyislessthan60point,DXCwillgiveupthispotentialsupplierandsearchforanothersupplier.

如果供应商的自我调查报告评分不低于60分时,采购开发部门则负责和新供应商进行沟通安排供应商现场评估,如果供应商的自我调查报告评分低于60分时,DXC将放弃该后备供应商并寻找新供应商。

7.2.2.ThesourcingdepartmentshallcoordinatewithQAandD&DdepartmenttoconducttheonsiteevaluationforthenewsupplieronthequalitycontrolaccordingtoSupplierchecklistreportbyDXCauditteam(Attachment8.4).

采购开发部门应当和品质部、开发部协调以便一起按照供应商品质稽核检查表(附件8.4)的内容对供应商进行现场评估。

7.2.3.Theresultoftheevaluationshallbeissuedbythesourcingdepartmentnotmorethan3daysaftertheauditwasfinished.

采购开发部门应在审核完成后的3个工作日之内发出评估结果报告。

7.2.4.Thenewsuppliershallberankaccordingtotheoutcomeoftheevaluationandbytheserating:

新供应商应当根据评估的结果按照以下规定划分等级:

RankA:

≥90points.----Excellentsupplier,mostpreferredsupplierforpurchase.

A级:

≥90分----供采购首选的优秀供应商。

RankB:

≥80pointsbut<90points----GoodSupplierthatDXCwilllikelytopurchasefrom

B级:

≥80分<90分----DXC较有可能选择的良好供应商。

RankC:

≥70pointsbut<80points-----Supplierwhichareconditionalaccept,DXCwillpurchasefromthissupplierwhenthereisanurgentrequirement.

C级:

≥70分<80分----有条件接受的供应商,较紧急的情况下DXC会选择该供应商。

RankD:

≥60pointsbut<70points-----ThesupplierneedtoimproveanddemonstratecompliancetoDXCrequirement,andneedsecondevaluationbeforepurchasing.

D级:

≥60分<70分----有待改善以证明能满足DXC要求,在采购前需再次评估。

RankE:

<60points-------DXCwillgiveupthispotentialsupplierandsearchforanotherone.

E级:

<60分-----DXC将放弃该后备供应商并寻找新供应商。

7.2.5.ThesupplierwhichfailsmorethanonetimeDXCwillgiveupthispotentialsupplierandsearchingforanothersupplier.

对于二次及以上次数未通过DXC审核的后备供应商,DXC将取消其后备供应商资格并寻找新的供应商。

7.2.6.WhenthesupplierbelongstoA,BorCrankafterevaluation,D&DdepartmentwillfollowtherequirementmentionedonthenewitemcreationformrequestthesuppliertopreparethesampleswithreferencespecificationforDXCD&DandQAdepartmentevaluationtoverifytheprocesscapability.

经评估后当供应商隶属A级,B级或C级,DXC开发部将按新物料诞生报告上所述规格要求该供应商提供样品并附有产品规格交DXC开发及品管评估,以验证其制程能力。

7.2.7.TheminimumratingthatthesupplierwillbelistedintheAVLisonlyforrankA,B&CandeachsupplierrankingshallappearintheAVL.

只有A、B、C级供应商才能列入合格供应商清单,并且在合格供应商清单中注明其等级。

7.2.8.ThesamplesfromthesuppliermustbeapprovedandthepricemustbefinalizedbetweenDXCandthesupplierbeforeupdatethenewsupplierintotheAVL.

在后备供应商进入合格供应商清单前,其提供的样品应已获批准并且其价格已商定好。

7.2.9.Incasethatthenewsupplierisashop,tradingcompanyorwithouttheirownmanufacturingworkshopandthebusinessvaluewithDXCislessthan100thousandRMBperyear,thissupplierwillbeconsideredastemporarysupplier.

如新供应商没有生产工厂或属商铺或为贸易公司且每年交货价值小于十万元人民币,此供应商将被定义为临时供应商.

7.2.10.ThetemporarysuppliershouldbelistedintheTemporarySupplierList.Itisnotmusttoevaluatethetemporarysupplier.Incasethetemporarysupplierwillbequalifiedasapprovedsupplier,thesupplierevaluationmustconduct.ThesuppliershallbequalifiedbeforeupdateitintotheAVL.

临时供应商需登录于《临时供应商清单》,对于临时供应商不要求进行评估,如临时供应商有条件调整为合格供应商时必须经过评估合格正式登录《合格供应商清单》。

7.3.Supplierannualevaluation供应商年度评估

Thesupplierannualevaluationincludestwoparts:

Supplierperformanceevaluationaccordingtothelastyearrecordsandsupplierannualaudit,theannualevaluationisnotnecessaryfortemporarysupplier.

供应商年度评估由两部份组成:

即供应商进行业绩评估(根据上一年度的相关记录进行评估)及供应商年度稽核,对临时供应商无需进行年度评估.

7.3.1.Supplierperformanceevaluation供应商业绩进行评估

Thesupplierperformanceevaluationincludesthequalityperformance,deliveryperformance,cooperationandcost.Theevaluationshallbeconductedonceayear(InJanuaryeveryyear),andinchargedbyQAdepartmentwithcooperationfrompurchasingandsourcingdepartment.

供应商业绩评估包括:

品质成绩、交期成绩、合作态度和成本,业绩评估应每年进行一次(在每年的一月份).此评估在采购部及采购开发部的配合下由品质部负责完成。

7.3.1.1.Theratingshallbesubdividedintodifferentcategoriesasbelow:

供应商等级应当按以下种类细分:

1).Qualityperformance:

40x(ALR1+ALR2……+ALR12)/12

ALR=Acceptedlots/totaldeliveredlotsx100%(monthly)

品质成绩:

40x(ALR1+ALR2……+ALR12)/12

ALR=合格批次/总批次x100%(月度)

2)Cost成本:

Priceisreasonable价格合理=10x100%

Priceisnotreasonable价格不合理=10x50%

3)Deliveryperformance:

30x(OTD1+OTD2……+OTD12)/12

OTD=Lotsdeliveredintime/totaldeliveredlotsx100%(monthly)

交期成绩:

30x(OTR1+OTD2……+OTD12)/12

OTD=按时交货批次/总交货批次x100%(月度)

4)Cooperationperformance:

20x(ROT1+ROT2….+ROT12)/12

ROT=CPARreplyOntime/TotalCPARx100%(monthly)

配合度:

20x(ROT1+ROT2….+ROT12)/12

ROT=按时回复的CPAR数/总CPAR数x100%(月度)

7.3.1.2.TheIQCsectionshallpublishthemonthlylotrejectionratetothesupplierandshallalsobepresentedtothemanagementduringthemonthlyqualityreview.

IQC部门需要向供应商提供提供其每月的拒收率统计结果,同时在公司召开品质月 会时将供应商的拒收率统计结果提供给公司管理层。

7.3.1.3.Therankoftheevaluationwillbesameasthenewsupplierratingsystem.

供应商的等级评估系统和新供应商的等级评估系统一致。

7.3.2.Annualsupplieraudit供应商年度稽核

7.3.2.1.Thesupplierafterselectionshallbeauditedafteraperiodnotexceedingone

(1)yearandexemptioncanbemadetosuppliersforthefollowingconditions:

供应商经选定后应至少每年进行一次稽核,在下列情况时可豁免:

7.3.2.1.1.Overseasupplier海外供应商

7.3.2.1.2.SupplierbelongstogradeAaccordingtotheyearlyperformanceevaluation

年度业绩评估结果属A级的供应商

7.3.2.2.Theauditcriteriashallbethesameasthecriteriafromfirstevaluation.

稽核标准应和第一次评估时的标准一致

7.3.2.3.Theauditcouldbeconductedfollowtheannualsupplierauditscheduleatthesuppliersiteorwhen:

年度稽核需根据年度稽核计划或在下列情况下进行:

7.3.2.3.1.ThereisanewproductshallbesuppliedtoD

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- SUPPLIER Control PROCEDURE中英文 PROCEDURE 中英文

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

《雷雨》中的蘩漪人物形象分析 1.docx

《雷雨》中的蘩漪人物形象分析 1.docx