yw1629履带液压挖掘机.docx

yw1629履带液压挖掘机.docx

- 文档编号:3586977

- 上传时间:2022-11-24

- 格式:DOCX

- 页数:16

- 大小:283.91KB

yw1629履带液压挖掘机.docx

《yw1629履带液压挖掘机.docx》由会员分享,可在线阅读,更多相关《yw1629履带液压挖掘机.docx(16页珍藏版)》请在冰豆网上搜索。

yw1629履带液压挖掘机

OPERATION

The[OPERATION]sectiondescribesthelocationofcomponentsandproperoperationofthecontrolcomponentsrequiredtooperatingthemachine.

Sufficientunderstandingofthissectionisnecessaryforsafeoperation.

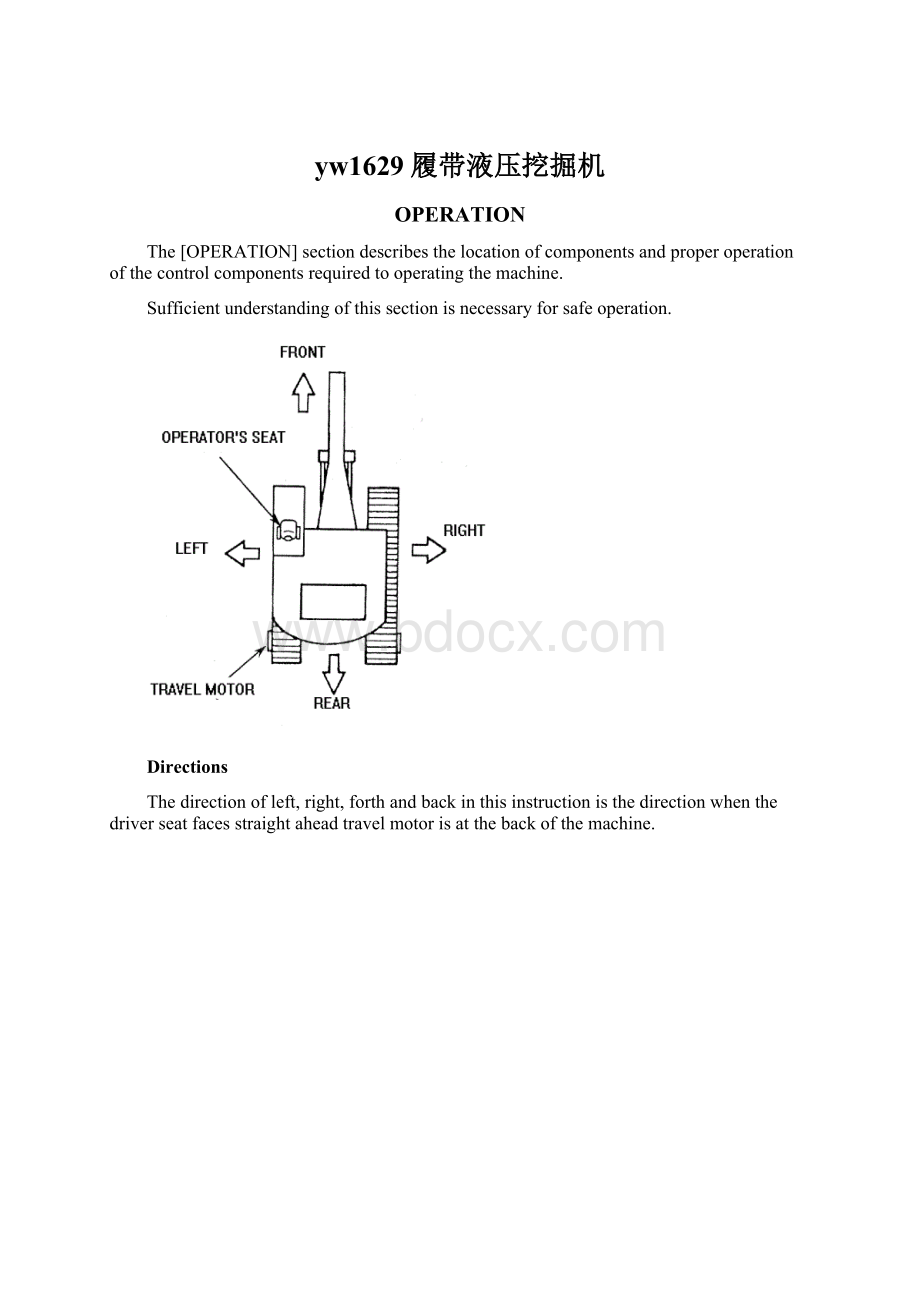

Directions

Thedirectionofleft,right,forthandbackinthisinstructionisthedirectionwhenthedriverseatfacesstraightaheadtravelmotorisatthebackofthemachine.

InstrumentsandControls

PedalsandLevers

1.DoorLockReleaseLever2.PilotControlLockLever3.LeftControlLever(withHornSwitch)4.LeftTravelLever5.LeftTravelPedal6.RightTravelPedal7.RightTravelLever8.RightControlLever

InstrumentPanel

1.

CombinedGauge(EngineOilPressureGauge,Ammeter,CoolantTemperatureGauge,andFuelLevelGauge)

2.AnnunciatorCell

3.EngineSpeedCounter(withServiceHourMeter)

SwitchPanel

1.FanSwitch2.PanelLamps/HeadlightsSwitch3.WorkingLightSwitch4.TravelSpeedSwitch5.KeySwitch6.Wiper/WasherSwitch

RadioPlayerandAir-conditionControl

1.Air-conditionControlPanel2.RadioPlayer

CautionsforUsingNewMachine

Besuretobreakinthenewmachinefor100hours(timeindicatedbythehourmeter)beforeworkingunderfullloadconditions.Takesufficientcareformaintenanceduringthisperiod.

Payattentiontorunningengine

1.Operatetheenginewithnormalload.Avoidoverloadingtheengine.

2.Inspectthepanellampsandgaugesduringoperating.

Every8hours(everyday)

1.Maintainfor8hoursoreveryday.(RefertoInspectionandMaintenanceCheckList——DailyCheck.)

2.Takecareforleakageofliquid.

3.Lubricatethepinsofattachmentduringtryoperatingorworkinginmuddyandwater.

Before50hoursfirst

1.Maintainfor50hours.(RefertoInspectionandMaintenanceCheckList——50hours.)

2.Inspecttorqueofboltsandscrews.(RefertoBoltTorqueofInspectionandMaintenancesection.)

InspectionbeforeStarting

Inspectthepanellampsandgauges

Insertthekeyintothestarterswitchandturntothe“ON”position.Allindicatorsshouldreverttostartposition.Toavoiddamagingthesurfaceofinstrumentpanel,wipingitwithsoftdishcloth.

Inspectliquidlevel

Inspecthydraulicoillevel,coolantlevel,andengineoilleveliscorrectwhether.Ifnot,refillordischargetheoilorwater,untiltheleveliscorrect.Thisinspectioncan’treplacethedailycheck.

OperatingEngine

Startingtheengine

1.Insertthekeyintothestarterswitchand

turntothe“ON”position.

2.Afterinspectingthepanellampsandgauges,turnthekeyfromthe“ON”positiontothe“START”positiontostartingtheengine.Whentheenginestarts,removeyourhandandthekeywillautomaticallyreturnto“ON”position.Don’tcontinuetorunthestarterformorethan10seconds.Iftheenginecan’tbestartedinonetry,thenwaitfor30secondsbeforetryingagain.

Stoppingtheengine

Iftheengineisnotstoppedaright,theturbochargermaybespoilt.

1.Parkthemachineonflatground,andlowerthebuckettotheground.

2.Keeptheenginerunningwithlowidlespeedfor3minutes.

3.Turnthekeyinthestarterswitchtothe“OFF”position,andpullthekeyout.

4.Raisethepilotcontrollocklevertothe“OFF”position.

Traveling

Whentravelforalong-distance,swingtheupperstructurethatletthetravelmotoratrearofthemachine.Operatethetravelleversorpedalsslowlywhentravelingonaslope.

Traveling

1.Simultaneouslystepontheforesideoftheleftandrighttravelpedalsorpushtheleftandrighttravelleversforwardandthemachinewillmoveforward.

2.Simultaneouslystepontherearwardoftheleftandrighttravelpedalsorpulltheleftandrighttravelleverstowardsyouandthemachinewillmovebackward.

3.Thetravelingarrestercanautomaticallybrake,whenthetravelpedalsorleversatneutral.

Turning

1.Stepontheforesideofthelefttravelpedalorpushthelefttravelleverforwardandthemachinewillturnright.

2.Stepontheforesideoftherighttravelpedalorpushtherighttravelleverforwardandthemachinewillturnleft.

3.

Simultaneouslyoperatetheleftandrighttravelleversinoppositedirectionsandthemachinewillturnonthespot.

Travelspeedcontrol

NOTICE:

Whentravelingonaslope,travelatlowspeed(Tortoise),anddon’tchangetohighspeed(Rabbit).

Operatingthetravelchangeswitch5mayattainhighspeed(Rabbit)andlowspeed(Tortoise).

Don’tchangetravelmodesduringtraveling.Stopthemachineandthenchangespeeds.Whentravelingonaslopeorinacongestedarea,travelatlowspeed(Tortoise)

.

Cautionsfortraveling

NOTICE:

Whentraveling,swinging,operatingthemachineinacongestedarea,provideasignalman.

1.Toavoidthetrackfrozenwithground,parkingthemachineonhardground.Whentheyfrozen,raisethetrackbyloweringtheboom.Toavoidharmingtheidlerandtrack,takecaretooperatethemachine.Iftheenginestoppedwithload,immediatelytakeofftheloadandstarttheengine.Continuetoruntheenginefor30secondswith1200r.p.m.

2.Beforeoperatingthetravellevers,verifythedirectionofthetravelmotors.

3.Whentraveling,selectflatandhardgroundasmuchaspossible.Travelingthemachinestraightasmuchaspossible.

4.Whentraveling,checkthebridgecapacityorthestrengthoftheroadshoulder.

5.Whentravelingonpavedroads,placeboardstopreventdamagetotheroadsurface.Takecaretotravelthemachineonbituminousmacadaminsummer.

6.Whentravelingcrossrailway,placeboardstopreventdamagetotherailway.

7.Don’tusethemachinenearthevergeofelectricalcableandbridge.

8.Whentravelingcrossariver,measurethedepthoftheriverwithbucket,andtravelatlowspeedmode.Whenthesurfaceofwaterishighthanthetopendofthetrackroller,don’tcrosstheriver.

9.Reducethetravelspeedwhentravelingonroughground,whichwillreducethepossibilityofdamagingthemachine.

10.Avoidoperationthatdamagingthetrackandthecrawler.

11.Toavoidslipping,wipeoffthesnowandiceonthetraceshoesbeforeloadandunloadthemachine.

Parking

1.Parkthemachineonflatgroundandlowerthebuckettotheground.

2.Bringtheengineintolowidlespeedforabout3minutes.

3.Turnthekeyinthestarterswitchtothe“OFF”positiontostoptheengineandpulloffthekey.

4.Raisethepilotcontrollocklevertothe“OFF”position.

IMPORTANCE:

Forthereasonthattheelectricalcomponentsinthecabarenotdamagedbythebadweather,closethewindowsandgateofthecabwhenparking.

Operating

Gatelocklever

Thegatelocklevercontrolsoiltransportedtopilotvalve.Themachinecan’tbeoperatingwithmisplayingtheleverswhenthegatelockleveratthe“OFF”position.

NOTICE:

Toavoidthemachinemoveaccidentally,inspectthegatelockleveratthe“OFF”positionwhetherornot.Raisethegatelocklevertothe“OFF”positionwhenyoudon’toperatethemachine,leavetheoperator’sseat,ortransportthemachine.

Controllevers(standardmode)

Themarkerthatshowtheoperatemodeoftheleversandpedalsisaddedinthecab.

Becarefulofinterferencebetweenthetracksandtheboomcylinderduringdigging.Fortheloadofthetracksreducedandtheinvariabilityandthehoistabilityaugmentedasmuchaspossible,thetravelmotormustatrear.

Whentheleversisreleased,theyreturnneutralautomatically,andthemovementwillbestopped.

NOTICE:

Anypartofbodydoesn’textendouttherailingofwindows,otherwiseyouwillbeharmedbyboomwhenmisplaythelevers.Iftherailingislostordamaged,replaceitimmediately.Knowwellaboutthepositionandthefunctionofeverylever.

1.SwingtoRight2.SwingtoLeft3.ArmSwayout4.ArmSwayin

5.Boomup6.Boomdown7.BucketDig8.BucketUnload

Raiseunilateraltrackwithboomandarm

NOTICE:

Lowerthebucketonthegroundandkeepthebucketcontactgroundwithcurvingpart.Keep90°~110°anglebetweentheboomandthearm.

Forraiseunilateraltrack,swingtheupperstructureabout90°angleandlowerthebucket.Blockunderthecrawlertopropupthemachine.

Operatinginsoftground

Don’ttravelonthegroundthathasnotenoughstrengthtopropupthemachine.

Ifthemachineworksinverysoftgroundorthetracksareblocked,youarelikelytocleanthecrawler.

Forraiseunilateraltrack,swingtheupperstructureabout90°angleandlowerthebucketontheground.Keep90°~110°anglebetweentheboomandthearm.Andkeepthebucketcontactgroundwithcurvingpart.

Runtheraisedtrackfrontandbacktowipeoffthedirtanddustonthetrack.

Reducetheenginespeedandtravelspeed,carefullytravelthemachinetosubstantialground.

Whenitisblockedbuttheenginecanbeoperated,themachinecanbetowed.Butthewireropemustbeattachedaright.

Preventturnover

Preventtravelacrossaslope.Whentravelonaslope,travelalongthemaximumangle.Don’tswingthebucketdownwardanymorethannecessary.Ifthemachinebecomesunstable,lowerthebucketandstopthemachine.

Topreventthemachineturnover,keepthebucketupwardwhenswingwithheavyload.Don’tswingthebucketdownward.Ifnecessary,reducetheswingspeed.

Operatinginwaterormud

Themachinecanworkinwaterthatuptouppertrackrolleronlywhentheworkareahasenoughstrengthtopreventthewaterexceedsuppertrackrollerasaresultofsinking.

Ofteninspectthemachinewhenworkinginthiscondition.Removethemachine’splaceinnecessary.

Preventsubmergetheswingbearing,swinggear,androtaryconnection.

Iftheswingbearing,swinggear,androtaryconnectionaresubmerged,takeoutthedrainplug,drainthewaterandmu

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- yw1629 履带 液压 挖掘机

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

转基因粮食的危害资料摘编Word下载.docx

转基因粮食的危害资料摘编Word下载.docx

《等式的性质》教学设计课件.ppt

《等式的性质》教学设计课件.ppt

押题宝典一级造价师之工程造价案例分析(交通)通关题库(附答案).pdf

押题宝典一级造价师之工程造价案例分析(交通)通关题库(附答案).pdf