SHJ38双螺杆挤出机配置之详细资料.docx

SHJ38双螺杆挤出机配置之详细资料.docx

- 文档编号:26963085

- 上传时间:2023-06-24

- 格式:DOCX

- 页数:12

- 大小:310.43KB

SHJ38双螺杆挤出机配置之详细资料.docx

《SHJ38双螺杆挤出机配置之详细资料.docx》由会员分享,可在线阅读,更多相关《SHJ38双螺杆挤出机配置之详细资料.docx(12页珍藏版)》请在冰豆网上搜索。

SHJ38双螺杆挤出机配置之详细资料

QuotationandSpecificationforSHJ-38Twinscrewsextruderline

Contentlist

1.DesignofLine

2.Price,PaymentandDeliveryTime

3.TechnicalDetailsforExtruder

4.TechnicalDetailsforPelletizer

5.TechnicalDetailsforVolumetricDosingSystem

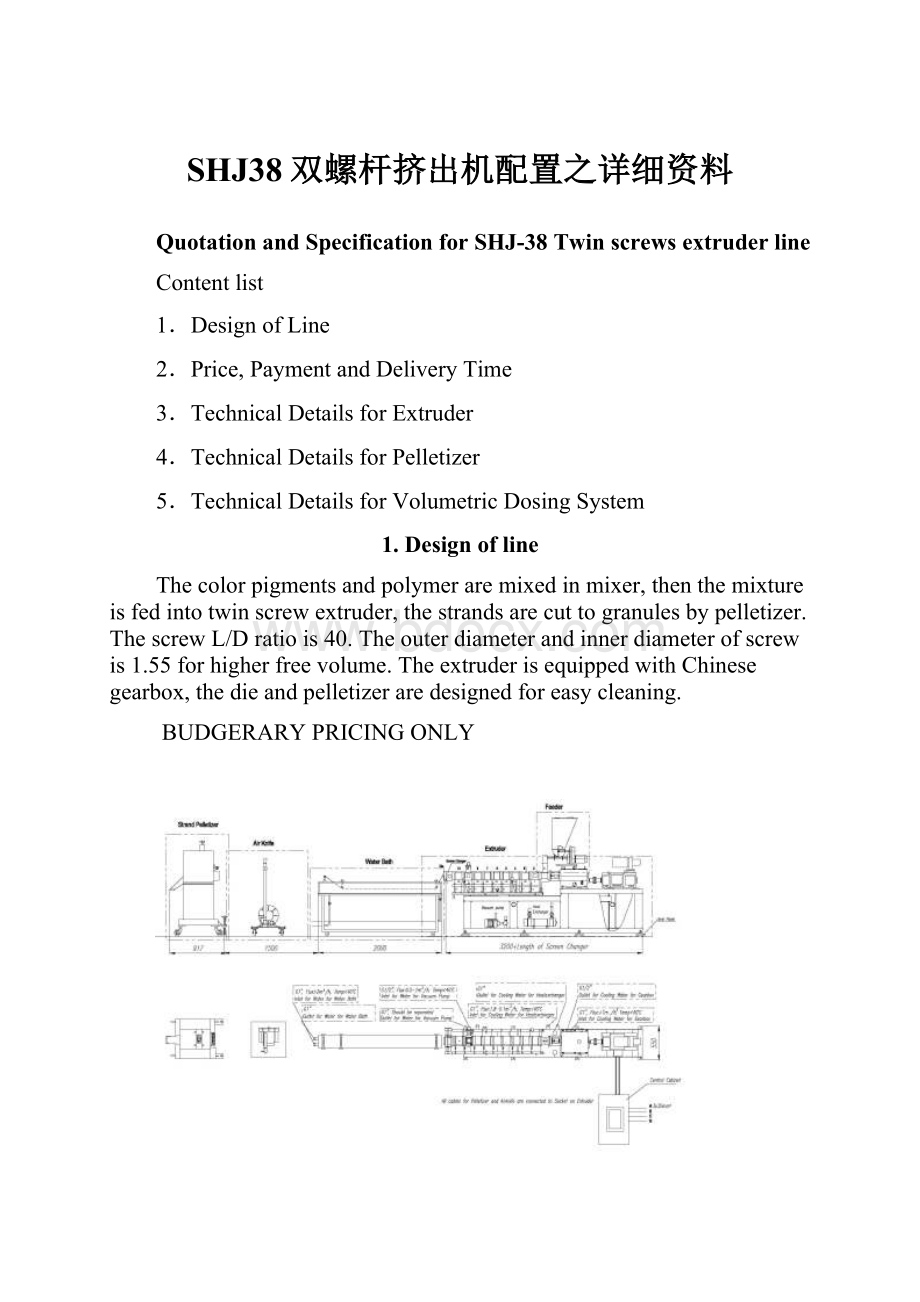

1.Designofline

Thecolorpigmentsandpolymeraremixedinmixer,thenthemixtureisfedintotwinscrewextruder,thestrandsarecuttogranulesbypelletizer.ThescrewL/Dratiois40.Theouterdiameterandinnerdiameterofscrewis1.55forhigherfreevolume.TheextruderisequippedwithChinesegearbox,thedieandpelletizeraredesignedforeasycleaning.

BUDGERARYPRICINGONLY

1.1Utilities

AllACmotorsworkat460V-480V,3phase.

Heatersworkat220V-240V,1phase

Instrumentsworkat110V-120V,1phase

2.Price,PaymentandDeliveryTime

2.1PriceFCA(USD)

Goodsdescription

Quantity

Price

Mainfeeder

1

1440

SHJ-38Twinscrewextruder

MainMotor(30kW)

ReducingandDistributingGearBox

Processingsection

Watermanifoldforcoolingbarrels

CoolingWaterUnit

More3temperaturecontrolzonesincluding3xtemperaturecontrollerforscreenchanger,3switchesforheaters,2solidrelays.

Diehead

Controlcabinet

1

29700

WaterBath

1

1056

AirKnife

1

925

StrandPelletizer(4kW)

1

5280

ClassifyingScreen

1

1980

StandardSpareParts

Screwelements500mm,solenoidvalve2pcs,Heatingelements8pcs,Fixedknife1pc

Totalprice

$40.381

2.2Payment

30%depositbywiretransferwithPO,65%paymentbywirewhenreadytoship,

5%Net30afterdelivery

2.3DeliveryTime

Approx.10to12weeksafterreceiptofdeposit,unitwillbereadyforshipmentfromChina.Doesnotincludeshipping,importduties,taxesorbrokeragefees.

SpecificationforSHJ-38Twinscrewsextruder

3.Technicaldetails

3.1Specification

3.2Descriptionoftheindividualunits

3.2.1maindriveunit

Z4DCmotor,

Technicaldata

Power:

30kW

Degreeofprotection:

IP54

Max.speed:

1500rpm

3.2.2Reducinganddistributinggearbox

Technicaldata

Speedreducingratio:

2.5

Maximumspeedinputshaft:

1500rpm

Maximumspeedoutputshaft:

600rpm

Permissibleoutputtorque/shaft:

245Nm

Description

Case-hardenedandgroundgearwheels

Involutesgearteethcouplingbetweentheoutputshaftsandscrewshafts

Gearboxconnectionpiecetothefirstbarrelsection

Integratedthrustbearingassembly

Gearboxcasingindistortion-resistant,vibration-freedesign

Splashlubrication

3.2.3Couplingconnectsmotorandgearbox

Coverforcouplingconnectsmotorandgearbox;

3.2.4Coulpingconnectsgearboxandscrews

Coverforcouplingconnectsgearboxandscrews;

3.2.4Processingsection

Screw

Diameter:

38mm

L/D=40:

1

Materials:

Toolsteel

Thescrewsetisconfiguredinaccordingwiththeprocesstaskandprocessconditions.

Closelyintermeshingscrewprofilewithscrewsthatareself-wipingatnarrowclearance

Screwelementswithvariouspitchesandlengths

Kneadingblockswithvariousanglesofstagger,numbersofkneadingdisksanddiskwidths

Involutesgearteethconnectiontoensurepowerflowbetweenthescrewshaftandscrewelements。

ScrewDesign

PleasespecifysizeofpelletswillbefedintoscrewsothatIamendscrewdesign.

Belowisdraftofdesign:

Barrels

Thebarrelsareconfiguredinaccordingwithprocesstaskandprocessconditions.

Tenbarrels,L/Dofperbarrelis4

Intensivecoolingofthebarrelsectionswithwaterisensuredbyaninternalboresystem,withboresarrangedclosetotheinsidebarrelwall

Thefirstbarrelisforfeeding,the9thbarrelisfordegassing(Presetorclosed?

)

Dependingontheprocesstask,thefollowingcanbesuppliedinaddition:

Plugstoclosethedevolatilizationopenings(Presetorclosed?

)

Additionaltemperatureandpressuremeasuringpoints

Devolatilizationports(Presetorclosed?

)

Speciallydesigneddegassingportforavoidingoverflow(Presetorclosed?

)

Barrelsupport

Specialdesignforvibration-freeandheatdistortion-resistant

1stsupportpoint:

4thbarrel

2ndsupportpoint:

9thbarrel

3.2.5Heatingsystem

Heaterwithinsulatedlayer.

Totalheatingpower:

approx.20kW

Heatingpowerforperclosebarrel:

1.92kW

Heatingpowerfordegassingbarrel:

1.35kW

Heatingpowerforadapter:

1.1kW

Heatingpowerfordie:

1.1kW

StainlesssteelcoveronHeaters

3.2.6Coolingsystem

Mediaforcoolingbarrel:

Distilledwater

Thefeedbarreliscooledbymeansofamanuallyadjustablevalve

Theothersbarrelsareautomaticcontrolled.

Volumeofwatertank:

45L

Powerofwaterpump:

0.5kW

Solenoidvalve:

madebyGermanBukertCo.,Ltd.

Manifoldaremadeofstainlesssteel.

3.2.7VacuumDegassingUnit

None

3.2.8Controlcabinet

DCmotordriver:

590seriesmadebyUKEUROTHERMCo.

Temperaturecontroller:

ShinkoJCR-33A-R/M-DR-C5 programmedforheat/cool/alarm+communicationinterfaceRS/485

Solidstaterelay:

madebyUSCDROMco.

Terminal:

madebyAustralianUTILUXCo.

Button,Indicatorlight,buzzerallhavepassedCE,ULcertification

Interlock:

Themachinewillstopwhenmeltisoverpressureandmainmotorisoverload.

Extruderisconnectedtocontrolcabinetwithaeroplugandsocket

Themachineisprotectedagainstthefollowingfaults:

Overload

Productoverpressure

Oiloverpressureorunderpressure

Overtemperatureorundertemperatureinscrewbarrel

DCmotordriverfault

Torquelimitedcouplingconnectsmotorandgearbox;

Overloadprotectionformotor;

Overtemperatureprotectionformotor;

Overmeltpressureprotection.

3.2.9Safetyinterlock:

Forpelletizercover

4.SpecificationforStrandCuttingSystem

4.1AdapterandDie

Heatedadapterbetweenoutletextruderdieplate.

DiameterofDieHole:

4.0mm,holesnumber:

10

HingedDie

Thedieplateisdesignedforeasilycleaningandremovingscrews,especiallyformasterbatch.

4.2Waterbath

Description

Basinmountedinawheeledguidableframewhichisadjustableheight

Inletvalveforcoolingwater

Drainvalveemptyingofthewaterbath

Overflow

Strippingdevicetoremovesurfacehumidityfromthepolymerstrands

Deflectionpulleystoguidethepolymerstrands

Technicaldata

Length3000mm

Width400mm

Depth250mm

Height800-1100mm

Watercapacityapprox.300l

4.3Airknife

Description

1blowingnozzlerow

1blowerwithdrivemotor

1hingedcover

Coverformotorforairknife

Technicaldata

Motorpower2.2kW

4.4Strandpelletizer

4.4.1XQ-100pelletizerForMasterbatch

PelletizerXQ-100,itisdesignedforeasilycleaning,especiallyformasterbatch.

Description

Rotatingknifeouterdiameter100mm

Rotatingknifewidth100mm

Regulationboundofthestationaryknife3mm

Pelletizingstripnumber(max)15strips

Output~150kg/h

Rotatingspeedofthecuttingknife62.5~625r/min

2feedrollers

1cuttingrotor

1infinitelyvariabledriveunitwithelectricmotor

ACMotorpower:

4kW

4.5ClassifyingScreen

Description

Doublelayers

Threeoutletforoverlong,undershortandnormalgranules.

Technicaldata

Vibrationmotor:

2x0.2kW

Meshdiameter:

4.2mm

4.Mainfeeder

Description

Thereisanagitatorforavoidingbridge

Allpartsincontactwithbulkproductsaremadeofstainlessmaterials

Technologydata

Screwdiameter:

30mm;madeofstainlesssteel

Motorpower:

0.75kW

Speedreducingratio:

17

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- SHJ38 双螺杆挤出机 配置 详细资料

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

《崔万志演讲观后感》.docx

《崔万志演讲观后感》.docx