哈工大机械原理大作业凸轮23Word文档格式.docx

哈工大机械原理大作业凸轮23Word文档格式.docx

- 文档编号:21590012

- 上传时间:2023-01-31

- 格式:DOCX

- 页数:22

- 大小:164.03KB

哈工大机械原理大作业凸轮23Word文档格式.docx

《哈工大机械原理大作业凸轮23Word文档格式.docx》由会员分享,可在线阅读,更多相关《哈工大机械原理大作业凸轮23Word文档格式.docx(22页珍藏版)》请在冰豆网上搜索。

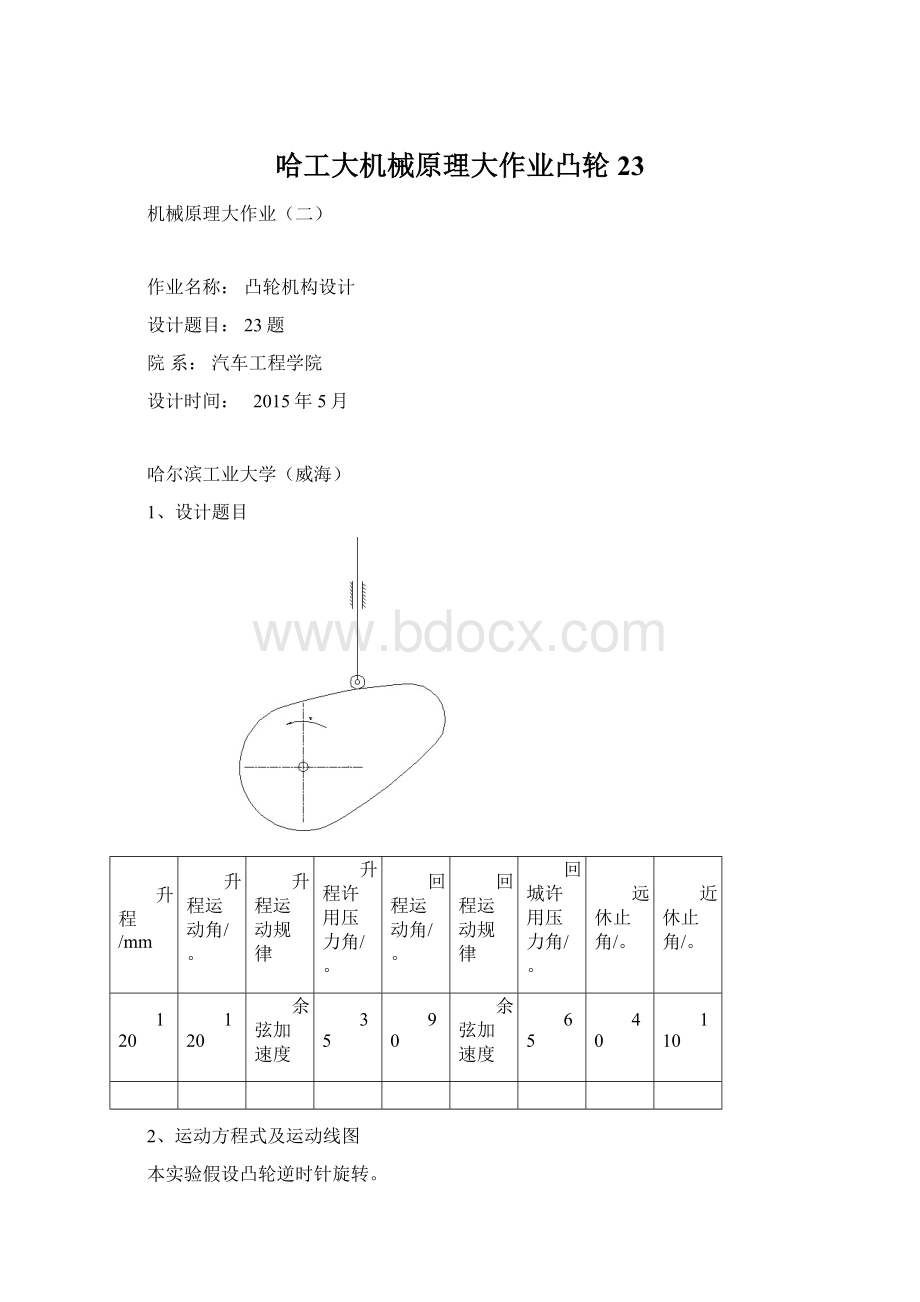

升程:

(0<

φ<

2π/3)

s=60*(1-Cos(1.5*φ))

v=90*Sin(1.5*φ)

a=135*Cos(1.5*φ)

远休止程:

s=120

v=0

a=0

回程:

(8*π/9<

25*π/18)

s=60*(1+Cos(2*(φ-8*pi/9)))

v=-120*Sin(2*(φ-8*pi/9))

a=-240*Cos(2*(φ-8*pi/9))

近休止程:

s=0

由上述公式通过编程得到位移、速度、加速度曲线如下:

位移S-转角φ曲线

速度V-转角φ曲线

加速度a-转角φ曲线

3、凸轮机构的

线图及基圆半径和偏距的确定

凸轮机构的

线图:

确定凸轮半径

偏距e取25,S取50.11

半径r=(e^2+s^2)^(1/2)=56

4、滚子半径的确定及凸轮理论廓线和实际廓线的绘制

滚子半径rr的确定:

下图为曲率-转角曲线,20mm>

Rmin>

10mm取滚子半径为10

理论轮廓(外部)和工作轮廓(内部)

理论轮廓.工作轮廓.基圆(大圆).偏距圆(小圆).滚子包络线(见下页图)

求位移、速度、加速度的程序

PrivateSubCommand1_Click()

DimsAsDouble

Dimf0AsDouble

DimfsAsDouble

Dimf01AsDouble

Dimfs1AsDouble

DimffAsDouble

DimfAsDouble

DimpiAsDouble

DimpaAsDouble

Picture1.DrawWidth=1

Picture1.Scale(-30,150)-(390,-30)

Picture1.Line(-30,0)-(390,0)'

XPicture1.Line(0,-30)-(0,150)'

Y

Picture1.CurrentX=0:

Picture1.CurrentY=130

Picture1.Print"

位移S"

Picture1.CurrentX=330:

Picture1.CurrentY=20

角度/度"

Fori=30To390Step30

Picture1.Line(i,5)-(i,0)

Picture1.CurrentX=i-7:

Picture1.CurrentY=0

Picture1.Printi

Nexti

Fori=30To150Step30

Picture1.Line(0,i)-(5,i)

Picture1.CurrentX=-20:

Picture1.CurrentY=i+2

Picture1.Printi

Nexti

Picture1.DrawStyle=2

Fori=-30To150Step30

Picture1.Line(-30,i)-(390,i),vbBlackNexti

Fori=30To360Step30

Picture1.Line(i,150)-(i,-30),vbBlack

Nexti

Picture2.DrawWidth=1

Picture2.Scale(-30,120)-(390,-150)

Picture2.Line(-30,0)-(390,0)'

X

Picture2.Line(0,-150)-(0,120)'

Picture2.CurrentX=0:

Picture2.CurrentY=100

Picture2.Print"

速度V"

Picture2.CurrentX=330:

Picture2.CurrentY=20

Picture2.Line(i,5)-(i,0)

Picture2.CurrentX=i-7:

Picture2.CurrentY=0

Picture2.Printi

Fori=-150To120Step30

Picture2.Line(0,i)-(5,i)

Picture2.CurrentX=-20:

Picture2.CurrentY=i+2

Picture2.DrawStyle=2

Fori=-150To120Step30

Picture2.Line(-30,i)-(390,i),vbBlack

Picture2.Line(i,120)-(i,-150),vbBlack

Nexti

Picture3.DrawWidth=1

Picture3.Scale(-30,280)-(390,-300)

Picture3.Line(-30,0)-(390,0)'

Picture3.Line(0,-300)-(0,280)'

Picture3.CurrentX=0:

Picture3.CurrentY=210

Picture3.Print"

加速度a"

Picture3.CurrentX=330:

Picture3.CurrentY=20

Picture3.Line(i,5)-(i,0)

Picture3.CurrentX=i-7:

Picture3.CurrentY=0

Picture3.Printi

Fori=-300To280Step60

Picture3.Line(0,i)-(5,i)

Picture3.CurrentX=-20:

Picture2.CurrentY=i+2Picture3.Printi

Picture3.DrawStyle=2

Fori=-300To280Step60

Picture3.Line(-30,i)-(390,i),vbBlack'

Picture3.Line(i,280)-(i,-300),vbBlack

pi=3.1415926

pa=pi/180

f0=120

fs=40

f01=90

fs1=110

s0=50

Forff=0To360Step0.01‘角度从0到360

f=ff*pa

Ifff<

f0Then

s=60*(1-Cos(1.5*f))

v=90*Sin(1.5*f)

a=135*Cos(1.5*f)

ElseIfff>

=f0Andff<

fs+f0Then

=fs+f0Andff<

fs+f0+f01Then

s=60*(1+Cos(2*(f-8*pi/9)))

v=-120*Sin(2*(f-8*pi/9))

a=-240*Cos(2*(f-8*pi/9))

ElseIfff>

=fs+f0+f01Andff<

=360Then

s=0

EndIf

Picture1.PSet(ff,s)

Picture2.PSet(ff,v)

Picture3.PSet(ff,a)

Nextff

EndSub

1.绘制凸轮机构dφ/ds–s线图程序

DimsAsDouble'

定义从动件位移

DimdsdfAsDouble'

定义ds/df

Dimdsdf2AsDouble

DimffAsDouble

DimfAsDouble

pi=4*Atn

(1)

Picture1.Scale(-180,170)-(270,-280)

Picture1.Line(-180,0)-(270,0)'

Picture1.Line(0,170)-(0,-280)

Picture1.CurrentX=10:

Picture1.CurrentY=130

S"

Picture1.CurrentX=130:

Picture1.CurrentY=20

dS/dφ"

Fori=-180To270Step20

Picture1.Line(i,5)-(i,0)

Picture1.CurrentX=i-7:

Fori=-280To170Step20

Picture1.CurrentX=-10:

Picture1.CurrentY=i+2

Fori=-280To170Step20

Picture1.Line(-180,i)-(260,i),vbBlackNexti

Fori=-180To270Step20

Picture1.Line(i,170)-(i,-280),vbBlack

Forff=0To360Step0.005

f=ff*pa

x=-dsdf

120Then

s=60*(1-Cos(1.5*f))

dsdf=90*Sin(1.5*f)

=120Andff<

160Then

s=120

dsdf=0

=160Andff<

250Then

dsdf=-120*Sin(2*(f-8*pi/9))

=250Andff<

dsdf=0

EndIf

Picture1.PSet(x,s)‘汇制dφ/ds–s曲线

3.确定偏距圆半径,基圆半径程序

DimdsdfAsDouble

Dimk1AsDouble

Dimk2AsDouble

Dimy1AsDouble

Dimy2AsDouble

Dimy3AsDouble

Picture1.Scale(-190,170)-(260,-280)Picture1.Line(-190,0)-(260,0)'

Picture1.Line(255,2)-(260,0)

Picture1.Line-(255,-2)

Y"

Picture1.Line(0,170)-(0,-280)'

Picture1.Line(-5,165)-(0,170)

Picture1.Line-(5,165)

X"

Fori=-190To260Step10

Picture1.CurrentX=i-7:

Fori=-280To170Step10

Picture1.Line(0,i)-(5,i)Picture1.CurrentX=-20:

Picture1.CurrentY=i+2

Fori=-280To170Step10

Picture1.Line(-190,i)-(260,i),vbBlackNexti

Fori=-190To260Step10

Picture1.Line(i,170)-(i,-280),vbBlackNexti

Forff=0To360Step0.005

x=-dsdf

Ifff<

dsdf=90*Sin(1.5*f)

EndIf

Picture1.PSet(x,s)

k1=-Cos(35*pa)/Sin(35*pa)

k2=Cos(65*pa)/Sin(65*pa)

y1=k1*x-82

y2=k2*x-22

y3=-k1*x

Picture1.PSet(x,y1),vbBlue

Picture1.PSet(x,y3),vbRed

Picture1.PSet(x,y2)

Nextff

4.计算曲率--确定滚子半径程序

DimeAsDouble

DimxAsDouble

DimyAsDouble

DimrrAsDouble

DimpaAsDouble

Dims0AsDouble

DimiAsDouble

DimdxdfAsDouble

Dimdxdf2AsDouble

DimdydfAsDouble

Dimdydf2AsDouble

DimdydxAsDouble'

Dimdydx2AsDouble

DimmAsDouble

PrivateSubForm_Load()

s0=50.11

e=25

Picture1.Cls

Picture1.Scale(-60,400)-(400,-60)

Picture1.Line(-60,0)-(400,0)'

Picture1.Line(0,-60)-(0,400)

Fori=-60To400Step20

Picture1.CurrentY=0Picture1.Printi

Picture1.Line(0,i)-(5,i)

Picture1.CurrentY=i+2

Fori=-60To400Step20

Picture1.Line(-50,i)-(400,i),vbBlackNexti

Picture1.Line(i,400)-(i,-50),vbBlackNexti

Forff=0To360Step0.01

Picture1.DrawWidth=2

dsdf2=135*Cos(1.5*f)

dsdf2=0

dsdf2=-240*Cos(2*(f-8*pi/9))

EndIf

y=(s0+s)*Sin(f)+e*Cos(f)

x=(s0+s)*Cos(f)-e*Sin(f)

dxdf=dsdf*Cos(f)-(s0+s)*Sin(f)-e*Cos(f)

dxdf2=(dsdf2-s-s0)*Cos(f)-(2*dsdf-e)*Sin(f)

dydf=dsdf*Sin(f)+(s0+s)*Cos(f)-e*Sin(f)

dydf2=(dsdf2-s-s0)*Sin(f)+(2*dsdf-e)*Cos(f)

dydx=dydf/dxdf

dydx2=((dydf2*dxdf-dxdf2*dydf)/(dxdf^3))

m=Abs(((1+dydx^2)^1.5)/dydx2)

Picture1.PSet(ff,m)

5.计算理论轮廓.工作轮廓.基圆.偏距圆.滚子包络线程序

DimhAsDouble

DimwAsDouble

DimvAsDouble

DimaAsDouble

Dimx1AsDouble

DimMAsDouble

rr=10

PrivateSubpush()'

推程计算f=ff*pa

s=60*(1-Cos(1.5*f))

v=90*Sin(1.5*f)

a=135*Cos(1

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- 哈工大 机械 原理 作业 凸轮 23

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

对中国城市家庭的教育投资行为的理论和实证研究.docx

对中国城市家庭的教育投资行为的理论和实证研究.docx