柴油机组检查记录表Word下载.docx

柴油机组检查记录表Word下载.docx

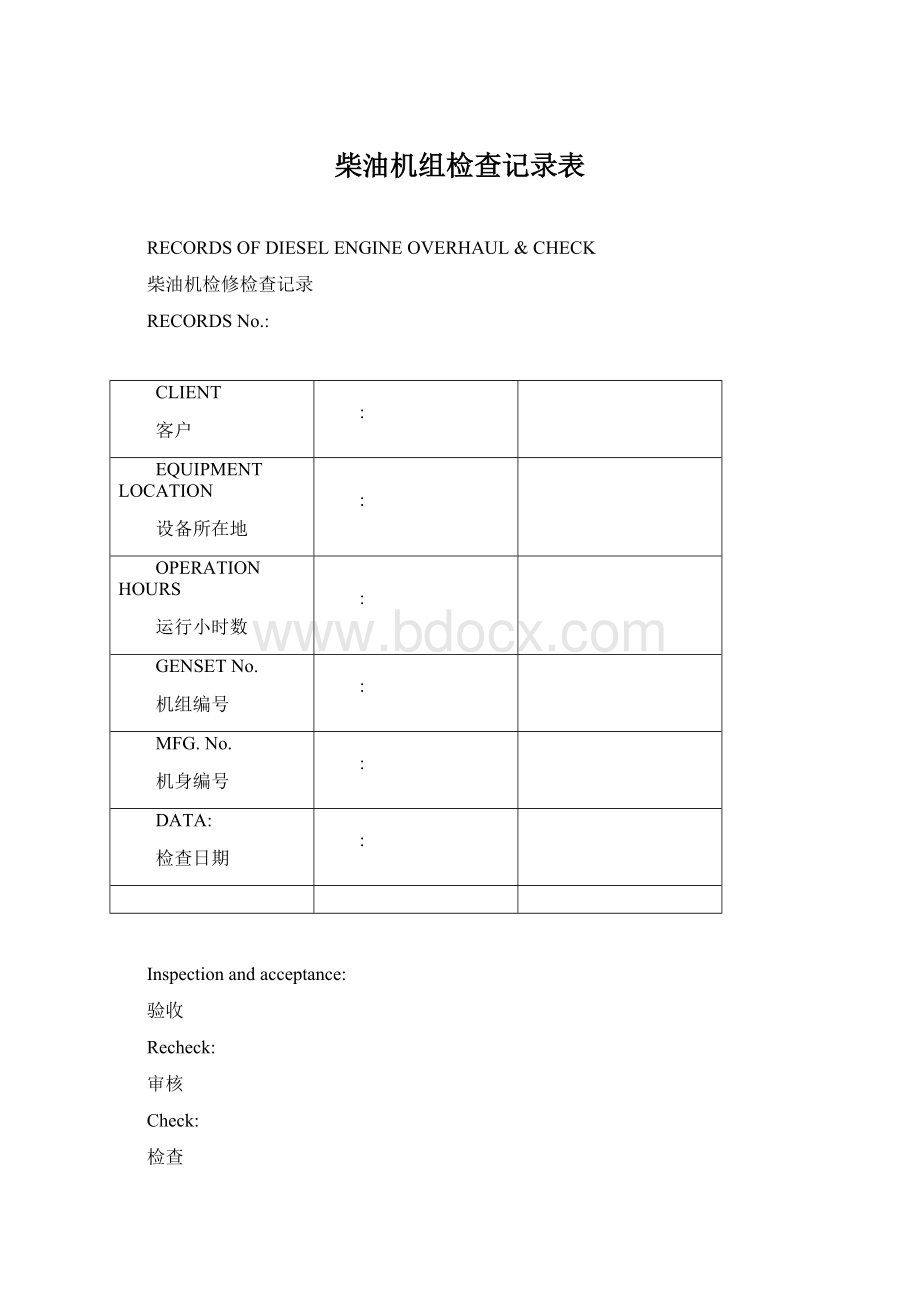

- 文档编号:20625812

- 上传时间:2023-01-24

- 格式:DOCX

- 页数:155

- 大小:3.50MB

柴油机组检查记录表Word下载.docx

《柴油机组检查记录表Word下载.docx》由会员分享,可在线阅读,更多相关《柴油机组检查记录表Word下载.docx(155页珍藏版)》请在冰豆网上搜索。

Measuringofmainbearingclearance主轴承间隙测量

3

A-4

Standardmeasuringof(outwardthrust)bearingclearance标准(外推力)轴承间隙测量

4

A-5

Standardmeasuringof(outwardthrust)bearingshellfreeopeninggap标准(外推力)轴瓦自由开口量测量

5

A-6

Measuringofengineopeningdifference发动机开档差测量

6

B

Connectionrodtest

连杆检测

B-1

Inspectionsheetforconnectionrod

连杆检查记录表

7

B-2

Inspectionsheetforconnectionrodbearing

连杆瓦检查记录表

8

B-3

Measuringoffreeopeninggapforconnectionrodbearing连杆瓦自由开口量测量

9

B-4

Measuringofcrankpin曲柄销测量

10

B-5

Measuringofclearancebetweenconnectionrodandcrankpin连杆瓦与曲柄销间隙测理

11

B-6

Measuringofconnectionrodsmall-endcopperbush连杆小头铜套测量

12

B-7

Measuringofconnectionrodbig-endinnerdiameter连杆大端内径测量

13

B-8

Magneticinspectionofconnectionrodbig-endtooth连杆大端齿面磁力探伤

14

B-9

Magneticpowerinspectionofconnectionrodbolt连杆螺栓磁粉探伤

15

B-10

Measuringofconnectionrodboltextension

连杆螺栓伸长测量

16

C

Pistoninspection

活塞检测

C-1

Inspectionrecordsforpiston活塞检查记录表

17

C-2

Measuringofouterdiameterforpistonandinnerdiameterforpistonpinhole

活塞外径和活塞销孔内么测量

18

C-3

Inspectionsheetforpistonpinshell(connectionrodsmallcopperbush)

活塞销瓦(连杆小头铜套)检查表

19

C-4

Measuringofouterdiameterforpistonpin

活塞销外径测量

20

C-5

Measuringofpistonringgrooveheight

洗塞环槽高度测量

21

C-6

Measuringofclearancebetweenpistonringandringgroove洗塞环和环槽间隙测量

22

C-7

Measuringofpistonringendclearance

活塞环对口间隙测量

23

D

Cylinderlinerinspection

罐套检测

D-1

Inspectionrecordsforcylinderliner

缸套检查记录表

24

Measuringrecordsforcylinderliner

缸套测量记录表

25

E

Inspectionofintake/exhaustvalve

进排气阀检测

E-1

Measuringofexhaustvalvespindle

排气阀杆测量

26

E-2

Measuringofexhaustvalvespindlebody

排气阀杆杆部测量

27

E-3

Measuringofexhaustvalveseatheight

排气阀盘座面的高度测量

28

E-4

Measuringofinnerdiameterofupper&

lowerguidepipeforexhaustvalvebox

排气阀箱上、下导管内径测量

29

E-5

Measuringofvalveseatheightforexhaustvalvebox排气阀箱的阀座高度测量

30

E-6

Measuringofheight&

clearanceforexhaustvalvebox&

cylinderheadmountingface

排气阀箱与缸头安装面高度和间隙的测量

31

E-7

Measuringofouterdiameterforintakevalvespindle进气阀杆外径测量

32

E-8

Measuringofintakevalveseatheight

进气阀阀盘高度测量

33

E-9

Measuringofinnerdiameterofintakevalveguidebush进气阀导套内径测量

34

F

Inspectionrecordforinjectionnozzle

喷油器检查记录

G

Inspectionrecordsforreliefvalve

安全阀检查记录

H

Rockerarmgear

摇臂机构

H-1

Measuringofintakerockershaftsleeveandrockershaft进气摇臂轴套和摇臂轴的测量

35

H-2

Measuringofintakerockershaftsleeveandrockershaft排气摇臂轴套和摇臂轴的测量

36

H-3

Measuringofrockerdrivegearguidesleeve

摇臂驱动机构导筒测量

37

H-4

Measuringofrockerdrivegearguidepillar

摇臂驱动机构导柱测量

38

H-5

Measuringofclearancebetweenrockerdrivegearguidesleeveandguidepillar

摇臂驱动机构导筒与导柱间隙测量

39

H-6

Measuringofinnerdiameteroftrolleyforrockerdrivegear摇臂驱动机构滚轮内径测量

40

H-7

Measuringofinnerdiameteroftrolleyforrockerdrivegear摇臂驱动机构滚轮外径测量

41

H-8

Measuringoftrolleyshaftsleeveclearanceforrockerdrivegear

摇臂驱动机构滚轮与轴套间隙测量

42

H-9

Measuringofinnerdiameterofshaftsleeveforrockerdrivegear摇臂驱动机构轴套内径测量

43

H-10

Measuringofouterdiameteroftrolleyshaftforrockerdrivegear

摇臂驱动机构滚轮轴外径测量

44

H-11

Measuringofclearancebetweenshaftsleeveandtrolleyshaftforrockerdrivegear

摇臂驱动机构轴套与滚轮轴间隙测量

45

I

Injectionoilpumpdrivegear

高压油泵驱动机构

I-1

Measuringofinnerdiameteroftrolleyandouterdiameterofshaftsleeveandclearanceforinjectionoilpump高压油泵驱动机构滚轮内径和轴套外径及其间隙测量

46

I-2

Measuringofinnerdiameterofguidesleeveandouterdiameterofguidepillarandclearanceforinjectionoilpump高压油泵驱动机构导筒内径和导柱外径及其间隙测量

47

I-3

Measuringofinnerdiameterofshaftsleeveandouterdiameteroftrolleyshaftandshaftsleeveclearanceforinjectionoilpumpdrivegear

高压油泵驱动机构轴套内径滚轮轴外径及轴套间隙测量

48

J

Measuringofcamshaftbearingclearance

凸轮轴轴承间隙测量

J-1

ARowclearancemeasuring列间隙测量

49

J-2

BRowclearancemeasuring列间隙测量

50

K

geiszlingervibrationdamperMeasuring盖斯林格曲轴减振器测量

L

Measuringofcamshaftdrivegeardentclearance凸轮轴驱动齿轮齿隙测量

M

Measuringofgovernordriveshaftsleeveclearance调速器驱动轴轴套间隙测量

N

Recordsforadjustmentstoadvanceangleofoilsupply

机组供油提前角调整记录

Basicparameterrecords

机组基本参数记录

DateofInspection:

MonthDateYear

检测日期:

年月日

InspectionSheetforMainShaftBushing

主轴轴瓦检测表

检查项目

BearingNo.

轴承号

Thrustbearing外推力轴承

Foreignscratch

异物刮伤

Bearingsurface

承压面

Back背面

Contusion撞伤

Airpocket气穴

Wear磨损

Color

颜色

Freeopeninggap自由开口量(mm)

~

下部盖的螺母标记错开量

Angle角度(°

)

Distance距离(mm)

Updateornot是否要更新

Remarks

备注

Note:

Marksshouldbemadefordismantledshaftbushing

注:

拆开的轴瓦应作好标记。

Dateofinspection:

MonthDateYear

Measuringrecordsformainbearing

主轴承测量记录

1.Mainbearing

主轴承

1-1Measuringofmainbearing

clearance

主轴承间隙测量

Bearingclearanceanduselimit轴承间隙和使用极限(mm)

Standardclearance标准间隙

Uselimit

使用极限

0.35~0.458

铜、铅层露出超轴瓦表面1/3时

Measurementvalueformainbearingclearance

主轴承间隙测量值(mm)

BearingNo.

1-2轴瓦自由开口量测量

Freeopeninggapandlimitvalue

自由开口量及其极限值(mm)

Standardvalue标准值

Uselimit使用极限

330~335

326

Measurementvalueforbearingbushfreeopeninggap

主轴承瓦自由开口量测量值(mm)

BushingNo.轴瓦号

Upperbushing上瓦

Lowerbushing下瓦

DateofInspection:

StandardBearingMeasurementRecords

标准轴承测量记录

1.Standardbearing标准轴承

1-1.Standardbearingclearancemeasurement

标准轴承间隙测量

StandardbearingclearancemeasurementvalueRadial&

axialclearanceandlimitforstandardbearingbush

标准

-2轴承间隙测量值(mm)标准轴承轴瓦径向和轴向间隙及限值(mm)

Radialclearance

径向间隙a

Axialclearance

轴向间隙b

Radialstandardclearance径向标准间隙

使用极限值

0.34~0.442

Emergenceofcopperandleadlayerisoveronethirdofsurfacearea.铜、铅层露出超1/3表面时

Axialstandardclearance轴向标准间隙

1.0

017~0.27

1-2Measurementofstandardbearing

expansionrate标准轴承膨胀度的测量

Measurementvalueforexpansionrate

膨胀量测量值(mm)膨胀量使用极限值(mm)

Standardvalue

标准值

350.2~353

350

Expansionrate

膨胀量

Upper上

Lower下

InspectionRecords

检查记录

Dateofinspection:

YearMonthDate

测量日期:

Measurementrecordsforengineopeningdifference

发动机开档差测量记录

MeasurementofcrankshaftopeningdifferenceUnit:

曲轴开档差测量单位:

(mm)

Crankshaftopeningdifference曲轴开档差

Bellcrank曲拐

Permissiblevalueincaseofthermalstate

机组热态时的许可值

Remarks备注

No.1bellcrank曲拐

-0.08≦d≦+0.00

Incaseofstandardbearinguse使用标准轴承时

Otherbellcrank其它曲拐

-0.06≦d≦+0.06

Permissiblevalueincaseofthermalstate

No.1曲拐

-0.02≦d≦+0.03

Incaseofstandardbearinguse使用标准轴承时

BellcranksfollowingNo.2bellcranksNo.2以后的曲拐

-0.01≦d≦+0.02

-0.02≦d≦+0.01

Measurementpointforcrankshaftopeningdifference

Indoortemp.室温

℃

Lub.oiltemp.

润滑油温度

Inspectionrecordsbeforedismantlingofpistons(Unit:

1/100mm)

未拆活塞前检测记录(单位:

1/100mm)

BellcrankNo.

曲拐号

No.1

No.2

No.3

No.4

No.5

No.6

No.7

No.8

No.9

Measuringpoint

测量

位置

SB

S

T

P

PB

Calculation

计算值

d

Inspectionrecordsafterremovingpistonconnectionrodgroup

吊出活塞连杆组后检测记录

Inspectionrecordsafterrestoringofmainbearings

装复主轴瓦后检测记录

Inspectionrecordsafterrestoringofpistongroup

装复活塞组后检测记录

Inspectionrecordsforthermalenginestataaftertesting

试机后热机状态检测记录

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- 柴油 机组 检查 记录

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

对中国城市家庭的教育投资行为的理论和实证研究.docx

对中国城市家庭的教育投资行为的理论和实证研究.docx