模具英语专业术语Word文档下载推荐.docx

模具英语专业术语Word文档下载推荐.docx

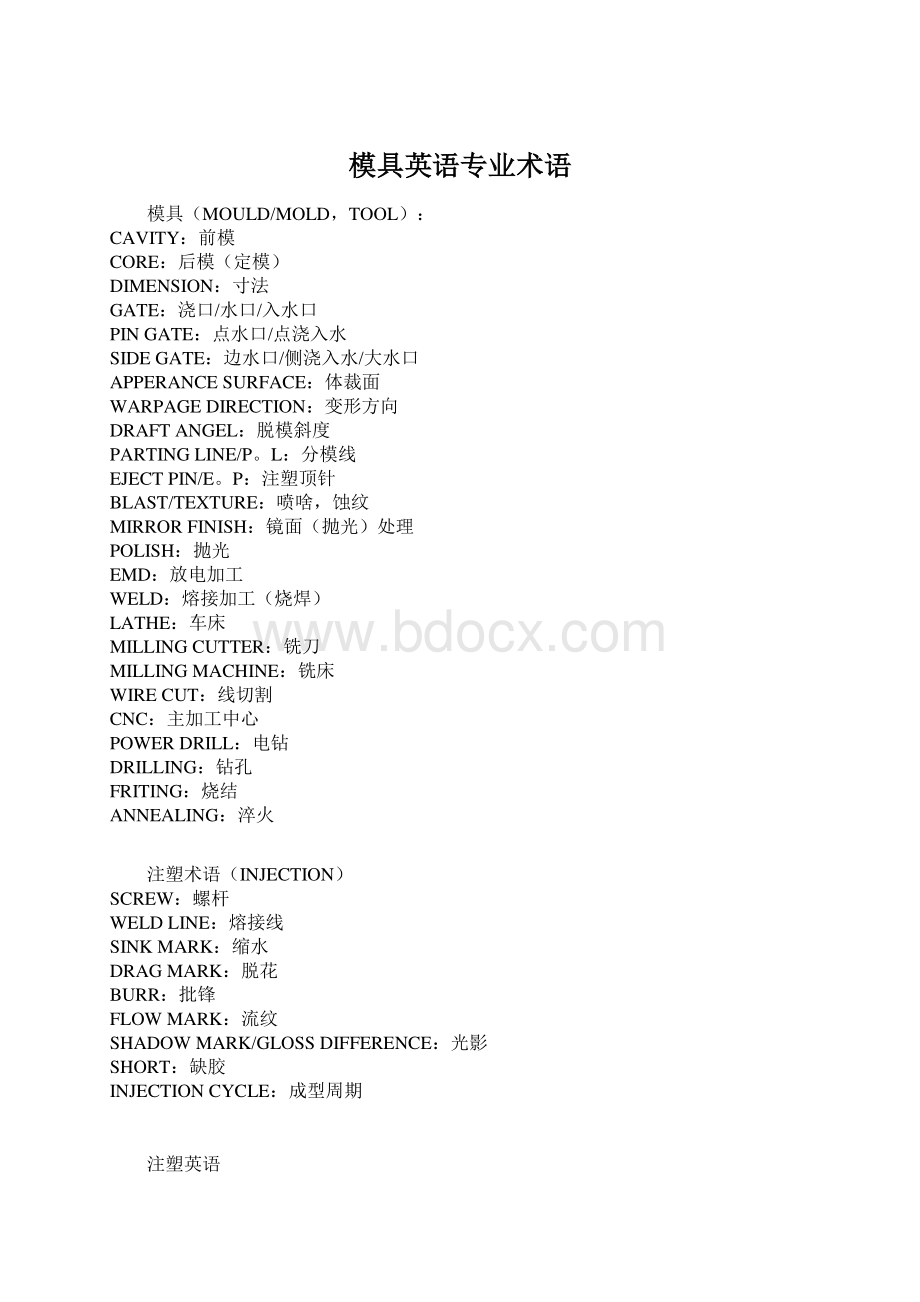

- 文档编号:20212493

- 上传时间:2023-01-19

- 格式:DOCX

- 页数:11

- 大小:20.99KB

模具英语专业术语Word文档下载推荐.docx

《模具英语专业术语Word文档下载推荐.docx》由会员分享,可在线阅读,更多相关《模具英语专业术语Word文档下载推荐.docx(11页珍藏版)》请在冰豆网上搜索。

铣刀MILLINGMACHINE:

铣床WIRECUT:

线切割CNC:

主加工中心POWERDRILL:

电钻DRILLING:

钻孔FRITING:

烧结ANNEALING:

淬火注塑术语(INJECTION)SCREW:

螺杆WELDLINE:

熔接线SINKMARK:

缩水DRAGMARK:

脱花BURR:

批锋FLOWMARK:

流纹SHADOWMARK/GLOSSDIFFERENCE:

光影SHORT:

缺胶INJECTIONCYCLE:

成型周期注塑英语型厚大小Thicksize锁模结构(机绞/直压)Modelockingstructure(machinetwists/straightpressure)最大开模距离Thebiggestdiesinkingisawayfrom动模板最大模具重量Movesthetemplatemaximummoldweight哥林柱间距Elderbrotherforestcolumnspacing顶出形式(电动五点,油压五点,油压十三点)Goesagainsttheform(electricallyoperatedfivespots,flowingtubingheadpressurefivespots,flowingtubingheadpressure13spots)顶出长度Goesagainstthelength顶棍孔直径Goesagainstthestickholediameter顶棍孔中心矩Goesagainstthestickholecentralmoment螺杆材质(合金)Screwrodmaterialquality(alloy)螺杆转速Screwrodrotationalspeed最大射出体积Projectsthevolumemostgreatly最大射出量Projectsthequantitymostgreatly射出率Ejectionrate每10mm射出量(理论)Each10mmprojectsthequantity(theory)射咀直径Shootsjuthediameter射咀R值ShootsjutheRvalue射咀空径Shootsjuthespatialdiameter定位环直径Locatingringdiameter溶胶能力Solability驱动方式(全自动/全液压)Drivetype(completelyautomatic/entirehydraulicpressure)电压Voltage电热功率Electricheatingpower电机功率Electricalmachinerypower作动油量Doesmovestheoilmass机械尺寸Mechanicalsize机械重量Mechanicalweight最高溶胶温度Highestsoltemperature是否带中子Whethertobringtheneutron是否带吹气Whethertohavetheairflus开模行程,openouldstroke定产,orderproduction定产效率,efficiencyoforderproduction注胶切换点,glue-injectionswitchingpoint保压压力1,protectivepressure倒索,inversesling模保护,mouldprotection关模低压,closemouldlowpressure炮筒温度,gunbarreltemperature回料量,returningamount注射压力,injectingpressure色母配比,rawcolorratiomixing配套摸具,matchedmold顶针次数,thimbletimes立式注胶机verticalinjector工艺卡,WSP(workspecificationprocedure)工作指导workinstruction注塑机部分英语钣金machinecover/uppercover/sidecover锁模部分clampingunit射胶部分injectionunit机架machineframe/base电气系统electricsystem液压系统hydraulicsystem机械系统mechanicalsystem机门safetydoor/fixeddoor/movabledoor锁模部分clampingunit电脑控制器computercontroller机械安全锁mechanicalsafetyinterlock射胶部分injectionunit液压系统hydraulicsystem电箱electricalcabinet/cable机架分体线standsplitline机架螺丝孔foundationbolthole机架machinebase/supportingframe理论注射容积theoreticalshotvolume实际注射量shotweight螺杆直径screwdiameter注射压力injectionpressure注射速度injectionspeed注射速率injectionrate螺杆长径比screwL/Dratio螺杆行程screwstroke螺杆转速screwspeed熔胶能力plasticizingcapacity锁模力clampingforce开模/锁模行程moldclamping/openingstroke模板尺寸platensize拉杆间距distancebetweentiebars/rods模板最大距离max.daylight容模量moldthickness(min.&

max.)顶出行程hydraulicejectionstroke顶出力hydraulicejectionforce顶针数nos.ofejectorpin液压系统压力hydraulicsystempressure油泵马达pumpmotor电热量heatingcapacity温度控制区数nos.oftempcontrolzones射嘴接触力nozzlecontactforceInjection注射Mouldclosing关模Coolingtime冷却时间Holdingtime保压时间Injectionstartdelay注射延迟Injectionalarmtime注射报警时间Finalcushionminimumvalue最后段位置Change-overtoholdingbyvalue切换到锁模Plasticizingendvalue预塑重终点Hydrarlicchange-overpressureholding切换到保压Screwvalueforchange-overtoholding加料Hydraulicpressureinholding锁模力Fillingstagepressurelimit充模压力Injectionspeed注射速度Plasticizingdelay预塑延时1stsuck-backspeed储料一速度1stsuck-backpressure储料一压力Screwrotationspeed螺杆转速Decompressionvalueatendofinjection注射终点Decompressionvalueatendofplasticizing预塑终点Mouldcloseforce关模压力Mouldclosingsafetytime.时间Mouldclosingpressure.压力1stclosingsafetystagepressure合模一段压力1stmouldclosingspeed.成型速度1ststagemouldclosingsafetyposition.位置Highpressurestartposition高压锁模位置注塑专业英语注塑专业英语SurfaceAppearance外观Glossiness/glossfinish光洁度Mattfinish/mattsurface毛面Glassfiberrichsurface/glassemergenceonthesurface玻纤外露Blooming/surfaceblooming表面析出Whitepatchesonsurface表面白斑Silvermarks/silverstreak银纹Splaymark水纹Flowmark流纹Weldline溶结纹Brittle/brittleness脆Bubbles/trappedgas气泡Void孔Burnmarks烧伤FRfailed阻燃不合格FlameratingV-2阻燃V-2Poordispersion分散不好FR/PTFEagglomeratesetc阻燃剂/PTFE结块Pelletporous粒子不密/蜜蜂窝Lowimpact/tensileetc物理性能低Highflow/fillercontentetc流动性/填充过高Longs/fines/doubles长粒/碎屑/连粒Poorcut粒形不好Bristle/voids表面有小气泡/孔Glassbundles玻纤结团Productwasrejecteddueto产品不能接受因为Highmoisturelevel高水分Warpage/warped翘曲Shrinkage/shrink收缩Sinkmarks缩影Shortshot/shortmolding打不满Distortion变形Overdimension尺寸过大Underdimension尺寸过小Flashing飞边Discoloration变色Offcolor颜色差异Flowrate流动率Viscous粘Highflow高流动Lowflow低流动Sticky粘Moldrelease脱模Antioxidant抗氧剂Flameretardantagent阻燃剂Heatstabilizer热稳定剂Choppedglassfiber短切玻纤Rovingglassfiber粗纱/长玻纤Glassbeads玻璃微珠Milledfiber碾磨纤Molybdenumdisulfide/moly/MoS2二硫化钼Colorant着色剂Pigment颜料Dye染料Acceptedproductspecification接受产品规格Approvedourproduct认可我们的产品Re-setspec重新定标准Addinextra添加多一点Reducedcontent减少含量Dropped/reducedbyx减少含量Confirmedcolorstandard确认颜色标准Approvedcolorstandard认可颜色标准Re-confirmedcolorstandard重新确认颜色标准Qualifiedourproduct认可我们的产品Undergoingheatagingtest在做热老化实验Productisundertesting产品在测试当中Receivedfirstorder接了第一个定单Expectedtofinishby预计在完成ExpectedorderisxMT预计定单量吨Estimatedannual/monthlyconsumption预计年/月用量-详细信息1.注射模具名称注射模:

Injectionmould热塑性塑料注射模:

Injectionmouldforthermoplasctics热固性塑料注射模:

Injectionmouldforthermosets无流道模:

Runerlessmould热流道模:

Hotrunnermould绝热流道模:

Insulated温流道模:

Warmrunnermould2.浇注,排溢,分型浇注系统:

Feedsystem主流道:

Sprue分流道:

Runner浇口:

Gate直接浇口:

Directgate;

Spruegate环行浇口:

Ringgate盘型浇口:

Diskgate;

Diaphragm轮辐浇口:

Spokegate:

Spidergate点浇口:

Pin-pointgate侧浇口:

Edgegate潜伏浇口:

Submarinegate护耳浇口:

Tabgate扇型浇口:

Fangate牛角浇口:

Horngate冷料穴:

Cold-slugwell浇口套:

Spruebush;

Spruebushing浇口镶块:

Gatinginsret分流锥:

Sprader流道板:

Runnerplate热流道板:

Manifoldblock;

Hot-runnermanifold温流道板:

Warmrunnerplate二级喷嘴:

Secondarynozzle鱼雷形组合体:

Torpedo;

Torpedobodyassembly管式加热器:

Cartridgeheater热管:

Heatpipe阀式浇口:

Valvegate加热腔:

Loadingchamber柱塞:

Forceplunger;

Potplungr溢料槽:

Flashgrorve;

Spewgrovve排气槽:

Vent分型面:

Partingline水平分型面:

Horizontalpartinghalf垂直分型面:

Verticalpartinghalf3.成型零件定模:

Stationarymould:

Fixedhalf动模;

Movablemould;

Movinghalf上模:

Uppermould;

Upperhalf下模:

Lowermould:

Lowerhalf型腔:

Cavity凹模:

Impression;

Cavityplate镶件:

Mouldinsert活动镶件:

Movableinsert;

Losedetail拼块:

Splits凹模拼块:

Cavitysplits型芯拼块:

Coresplits型芯:

Core侧型芯:

Sidecore:

slidecore螺纹型芯:

Threadplug;

Threadedcore螺纹型环:

Threadring;

Threadedcavity凸模:

Punch;

Force嵌件:

Insertformould4.支持与固定零件定模座板:

Fixedclampplate:

Topclampingplate;

Topplate动模座板:

Movingclampplate:

Bottomclampingplate;

Bottmplate上模座板:

Upperclampingplate下模座板:

Lowerclampingplate凹模固定板:

Cavity-retaierplate型芯固定板:

Core-retaierplate凸模固定板:

Punch-retaierpilte模套:

Chase;

Bolster;

Frame;

支撑板:

Backingplate垫块:

Spacerparallel支架:

Ejectorhousing支撑柱:

Supportpillar模板:

Mouldplate5.抽芯零件斜销:

Anglepin;

Fingercam滑块:

Slide;

Camslide侧型芯滑块:

Slidecore-slide滑块导板:

Slideguidestrip锲紧块:

Heelblock;

Wedgeblock;

Lockingheel斜槽导板:

Fingerguideplate弯销:

Dog-legcam斜滑块:

Angled-liftsplits6.导向零件导柱:

Guidepillar;

Guidepin;

Leaderpin带头导柱:

Straightleaderpin带肩导柱:

GuidepillarShouldered;

Shoulderleaderpin推板导柱:

Ejectorguidepillar;

Ejeectorguidepin导套:

Guidebush;

Guidebushing直导套:

Straight;

Straightbushing带头导套:

Shoulderbushing推板导套:

Ejectorguidebush;

Ejectorbushing7.定位和限位零件定位圈:

Locatingring锥形定位圈:

Mouldbaseslocatingelements复位杆:

Ejectorplatereturnpin;

Push-backpin限位钉:

Stoppin;

Stopbutton限位块:

Stopblock;

Stoppad定距拉杆:

Lengthbolt;

Pullerbolt定距拉板:

Pullerplate;

Limitplate8.推出零件推杆:

Ejectorpin圆柱头推杆:

Ejectorpinwithcytindricalhead带肩推杆:

Shoulderedejectorpin扁推杆:

Flarejectorpin推管:

Ejectorsleeve推块:

Ejectorpad推件板:

Stripperplate推件环:

Stripperring;

Stripperdlisk推杆固定板:

Ejectorretainerplate推板:

Ejectorplate;

Ejectionplate连接推杆:

Ejectortierod拉料杆:

Spruepuller钩形垃料杆:

Spruepuller;

Z-shaped球头垃料杆:

Ballheaded圆锥头垃料杆:

Conicalheaded分流道垃料杆:

Runnerpuller;

Runnerlockpin推流道板:

Runnerstripperplate9.冷却和加热零件冷却通道:

Coolingchannel;

Coolingline隔板:

Baffle加热板:

Heatingplate隔热板:

Thermalinsulationboard10.模架模架:

Mouldbase标准模架:

Standardmouldbase11.塑料成型模具的主要设计要素注射能力:

Shotcapacity收缩率:

Shrinkage注射压力:

Injectionpressure锁模力:

Clampingforce;

Lockingforce成型压力:

Mouldingpressure模内压力:

Internalmouldpressure;

Cavitypressure开模力:

Mouldopeningforce脱模力:

Ejectionforce抽芯力:

Core-pullingforce抽芯距:

Core-pullingdistance闭合高度:

Mouldshutheight最大开距:

Maximumdaylight;

Opendaylight投影面积:

Projectedarea脱模斜度:

Draft脱模距:

Stripperdistance

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- 模具 英语专业 术语

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

对中国城市家庭的教育投资行为的理论和实证研究.docx

对中国城市家庭的教育投资行为的理论和实证研究.docx