影响耐久性强度的因素 机械设计及制造专业外文翻译中英文对照Word文档格式.docx

影响耐久性强度的因素 机械设计及制造专业外文翻译中英文对照Word文档格式.docx

- 文档编号:19409959

- 上传时间:2023-01-06

- 格式:DOCX

- 页数:11

- 大小:332.82KB

影响耐久性强度的因素 机械设计及制造专业外文翻译中英文对照Word文档格式.docx

《影响耐久性强度的因素 机械设计及制造专业外文翻译中英文对照Word文档格式.docx》由会员分享,可在线阅读,更多相关《影响耐久性强度的因素 机械设计及制造专业外文翻译中英文对照Word文档格式.docx(11页珍藏版)》请在冰豆网上搜索。

Sizeofthesection

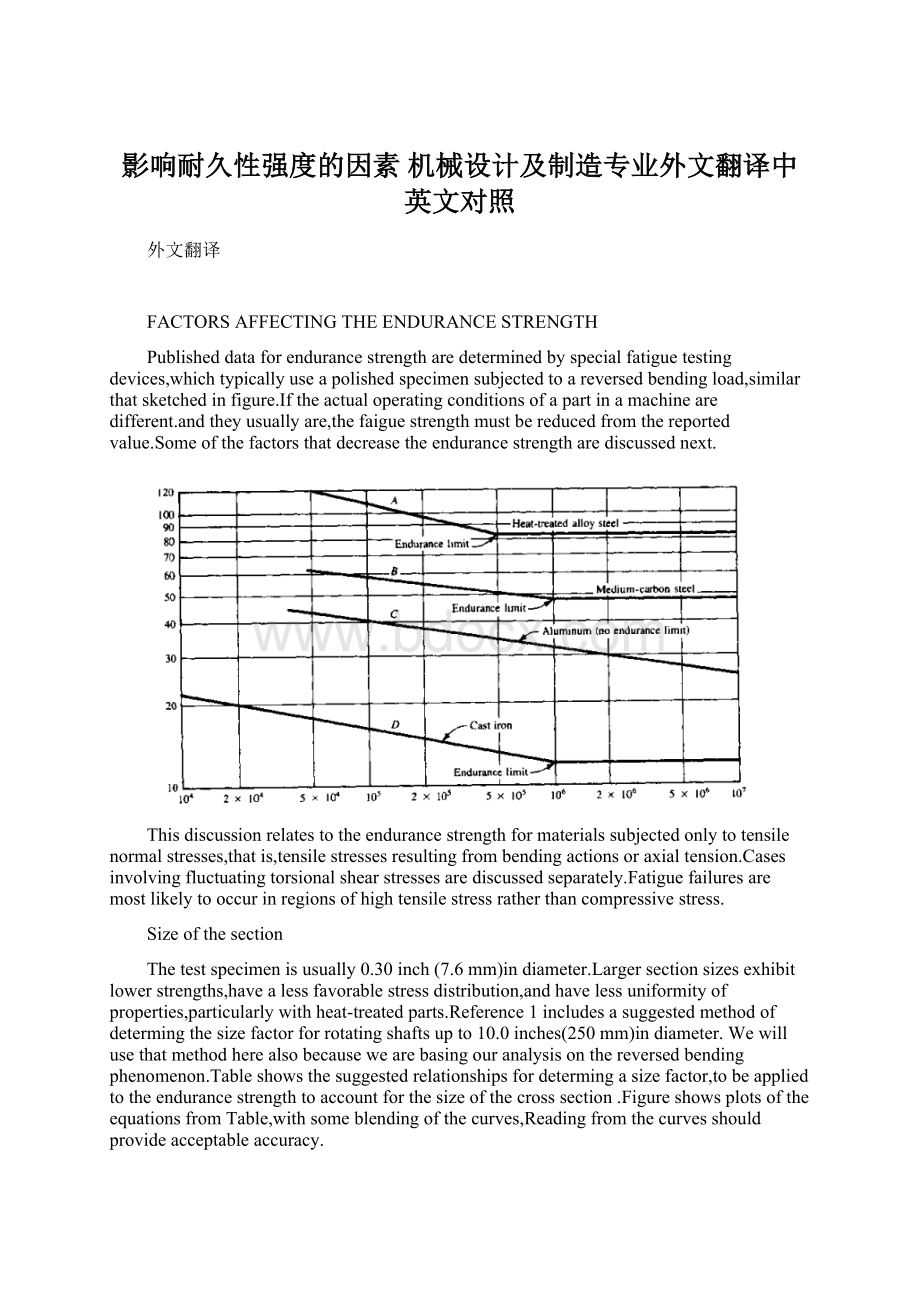

Thetestspecimenisusually0.30inch(7.6mm)indiameter.Largersectionsizesexhibitlowerstrengths,havealessfavorablestressdistribution,andhavelessuniformityofproperties,particularlywithheat-treatedparts.Reference1includesasuggestedmethodofdetermingthesizefactorforrotatingshaftsupto10.0inches(250mm)indiameter.Wewillusethatmethodherealsobecausewearebasingouranalysisonthereversedbendingphenomenon.Tableshowsthesuggestedrelationshipsfordetermingasizefactor,tobeappliedtotheendurancestrengthtoaccountforthesizeofthecrosssection.FigureshowsplotsoftheequationsfromTable,withsomeblendingofthecurves,Readingfromthecurvesshouldprovideacceptableaccuracy.

Whenthecomponentbeingdesignedisnotcircularlikeashaft,judgmentisrequiredtodeterminethecharacteristicdimensiontouseintheformulas.Forflat,rolledshapes,thethicknessshouldbeused.Notedthattheuseoftheseequationsisapproximate.

SurfaceFinish

Anydeviationfromapolishedsurfacereducesendurancestrength.Figureshowsroughestimatesfortheendurancestrengths,comparedwiththeultimatetensilestrengthofsteelsforseveralpracticalsurfaceconditions,Itiscriticalthatpartssubjectedtofatigueloadingbeprotectedfromnicks,scratches,andcorrosionbecausetheydrasticallyreducefatiguestrength.

StressConcentrations

Suddenchangesingeometry,especiallysharpgroovesandnotcheswherehighstressconcentrationsoccur,arelikelyplacesforfatiguefailurestooccur.Careshouldbetakeninthedesignandmanufactureofcyclicallyloadedpartstokeepstressconcentrationfactorstoalowvalue.Wewillapplythestressconcentrationfactors,asfoundfromthemethodsofSection,tothecomputedstresses,ratherthantotheallowablestrengths.

Flaws

Internalflawsofthematerial,especiallylikelyincastparts,areplacesinwhichfatiguecracksinitiate.Criticalpartscanbeinspectedbyx-raytechniquesforinternalflaws,Iftheyarenotinspected,ahigher-than-averagedesignfactorshouldbespecifiedforcastparts,andalowerendurancestrengthshouldbeused.

Temperature

Mostmaterialshavealowerendurancesstrengthathightemperatures.Thereportedvaluesareforroomtemperatures.Operationabove160°

F(72°

C)willreducetheendurancestrengthofmostductilematerials.

NonuniformMaterialProperties

Manymaterialshavedifferentmaterialpropertiesindifferentdirectionsbecauseofthemannerinwhichthematerialwasprocessed.Rolledsheetorbarproductsaretypicallystrongerinthedirectionofrollingthantheyareinthetransversedirection.

Fatiguetestsarelikelyhavebeenrunontestbarsorientedinthestrongerdirection.Stressingofsuchmaterialinthetransversedirectionmayresultinlowerendurancestrength.

Nonuniformpropertiesarealsolikelytoexistinthevicinityofweldsbecauseofincompleteweldpenetration,slaginclusions,andvariationsinthegeometryofthepartattheweld.

Also.weldingofheat-treatedmaterialsmayalterthestrengthofthematerialbecauseoflocalannealingneartheweld.

Someweldingprocessesmayresultinthproductionofresidualtensilestressesthatdecreasetheeffectiveendurancestrengthofthematerial.

Annealingornormalizingafterweldingisoftenusedtorelievethesestresses,buttheeffectofsuchtreatmentsonthestrengthofthebasematerialmustbeconsidered.

ResidualStresses

Fatiguefailurestypicallyinitiateatlocationsofrelativelyhightensilestress.Grindingandmachining,especiallywithhighmaterialremovalrates,alsocauseundesirableresidualtensilestress.Weldinghasalreadybeenmentionedasaprocessthatmayproduceresidualtensilestress.

Anymanufacturingprocessthattendstoproduceresidualstresswilldecreasetheendurancestrengthofthecomponent.Criticalareasofcyclicallyloadedcomponentsshouldbemachinedorgroundinagentlefashion.Processesthatproduceresidualcompressivestressescanprovetobebenefical.Shotblastingandpeeningaretwosuchmethods.Shotblastingisperformedbydirectingahighvelocitystreamofhardenedballsorpelletsatthesurfacetobetreated.Peeningusesaseriesofhammerblowsonthesurface.Crankshafts,springs,andothercyclicallyloadedmachinepartscanbenefitfromthesemethods.

CorrosionandEnvironmentalFactors

Endurancestrengthdataaretypicallymeasuredwiththespecimeninair.Operatingconditionsthatexposeacomponenttowater,saltsolutions,orothercorrosiveenvironmentscansignificantlyreducetheeffectiveendurancestrength.Corrosionmaycauseharmfullocalsurfaceroughnessandmayalsoaltertheinternalgrainstructureandchemistryofehematerial.Steelsexposedtohydrogenareespeciallyaffectedadversely.

Nitriding

Nitridingisasurface-hardeningprocessforalloysteelsinwhichthematerialisheatedto950°

F(514°

C)inanitrogenatmosphere,typicallyammoniagas,followedbyslowcooling.Impvovementofendurancestrengthof50%ormorecanbeachievedwithnitriding.

WroughtversusCastMaterials

Metalalloyshavingsimilarchemicalcompositionscanbeeitherwroughtorcasttoproducethefinalform.Wroughtmaterialsareusuallyrolledordrawn.Wroughtmaterialsusuallyhaveahigherendurancestrengththancastmaterialsofsimilarcompositioninregionswherenosignificantstressconcentrationexits.However,inthevicinityofnotchesandotherdiscontinuities,theendurancestrengthofwroughtandcastmaterialsismorenearlyequal.Onepossibleexplanationofthisphenomenonisthatthecastmaterialislikelytohavemoreisotropicmaterialpropertiesthanthewroughtmaterialandislessaffectedbythepresenceofthestressconcentration.

Tousethemoreconservativeapproach,itisrecommendedthatafactorof0.8beappliedtothebasicendurancestrengthifacaststeelisused.Forcastiron,afactorof0.70isrecommended.

TypeofStress

Endurancestrengthdataareobtainedfromtherotatingbeamtestthatproducescompletelyreversedandrepeatednormalstresses.Themaximumstressisproductedatthesurfaceofthespecimen,andthestressvaneslinearlytozeroatthecenterofthecircularcrosssection.Iftheactualloadingisdifferentfrombending,afactorforthetypeofloadingshouldbeappliedtotheendurancestrength.

AxialTension

Underpuretension,allofthematerial--notjustthesurface—issubjectedtothemaximumstress.Afactorof0.80issuggestedtobethebendingendurancestrengthtoreflectthisdifferentbehavior.

EffectofStressRatioonEnduranceStrength

Figure5-10showsthegeneralvariationofendurance-strengthdataforagivenmaterialwhenthestressratioRvariesfrom-1.0to+1.0,coveringtherangeofcasesincludingthefollowing:

■Repeated,reversedstress(Figure5-3);

R=-1.0

■Partiallyreversedfluctuatingstresswithatensilemeanstress【Figure5-4(b)】;

-1.0<

R<

0

■Repeated,one-directiontensilestress(Figure5-6);

R=0

■Fluctuatingtensilestress【Figure5-4(a)】;

0<

1.0

■Staticstress(Figure5-1);

R=1

NotethatFigure5-10isonlyanexample,anditshouldnotbeusedtodetermineactualdatapoints.Ifsuchdataaredesiredforaparticularmaterial,specificdataforthatmaterialmustbefoundeitherexperimentallyorpublishedliterature.

Themostdamagingkindofstressamongthoselistedistherepeated,reversedstresswithR=-1.(SeeReference2.page27.)RecallthattherotatingshaftinbendingasshowninFigure5-2isanexampleofaload-carryingmembersubjectedtoastressratioR=-1.

FluctuatingstresseswithacompressivemeanstressasshowninParts(c)and(d)ofFigure5-4donotsignificantlyaffecttheendurancestrengthofthematerialbecausefatiguefailurestendtooriginateinregionsoftensilestress.

NotethatthecurvesofFigure5-10showestimateoftheendurancestrength,Sn,asafunctionoftheultimatetensilestrengthforsteel.Thesedataapplytoidealpolishedspecimensanddonotincludeanyofetheotherfactorsdiscussedinthissection.Forexample,thecurveforR=-1.0(reversedbending)showsthattheendurancestrengthforsteelisapproximately0.5timestheultimatestrength(0.50×

Sn)forlargenumbersofcyclesofloading(approximately10orhigher).Thisisagoodgeneralestimateforsteels.ThechartalsoshowsthattypesofloadproducingRgreaterthan-1.0butlessthan1.0havelessofaneffectontheendurancestrength.Thisillustratesthatusingdatafromthereversedbendingtestisthemostconservative.

WewillnotuseFigure5-10directlyforprobleminthisbookbecauseourprocedureforestimatingtheactualendurancestrengthstartswiththeuseofFigure5-9whichpresentsdatafromreversedbendingtests.Therefore,theeffectofstressratioisalreadyincluded.Section5-9ofthischapterincludesmethodsofanalysisforloadingcasesinwhichthefluctuatingstressproducesastressratiodifferentfromR=

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- 影响耐久性强度的因素 机械设计及制造专业外文翻译中英文对照 影响 耐久性 强度 因素 机械设计 制造 专业 外文 翻译 中英文 对照

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

铝散热器项目年度预算报告.docx

铝散热器项目年度预算报告.docx

血液的一般检验4_精品文档.ppt

血液的一般检验4_精品文档.ppt