8D制作作业规范B1Word文档下载推荐.docx

8D制作作业规范B1Word文档下载推荐.docx

- 文档编号:16853160

- 上传时间:2022-11-26

- 格式:DOCX

- 页数:11

- 大小:75.62KB

8D制作作业规范B1Word文档下载推荐.docx

《8D制作作业规范B1Word文档下载推荐.docx》由会员分享,可在线阅读,更多相关《8D制作作业规范B1Word文档下载推荐.docx(11页珍藏版)》请在冰豆网上搜索。

影响的广度与深度为何?

受影响的料号、批号为何?

发生客户是谁?

缺点率等相关问题陈述的内容加以说明,明确说明真正的问题。

6-2-3Analysis&

Finding

分析与发现:

分析相关的异常信息,确认缺点或问题的形成过程,进行问题的澄清与验证。

确认问题所影响的制程范围,如回溯问题批号之生产纪录,关参数数据如管制图有无异常,L/A检验资料有无异常。

6-2-4ContainmentAction

防堵行动计划:

防堵计划应列出防堵对策结果有效的时间点,保证异常物料发生的期间内所有的物料皆已纳入并回溯确认该异常物料,以区隔正常与异常的物料。

计划中应列出确保其它的板子受到的影响程度减到最低。

若有重供货sorting的计划(e.g.screen,sourceinspectionetc.),应列入在计划中。

6-2-5RootCause

真正原因分析:

真正原因分析应将确认真正原因的实验或对策法列出,定出时程表及附相关数据分析之结果,作为真正原因的分析。

6-2-6CorrectiveAction

改善对策:

改善对策应包括对策执行与完成的时程表,能透过系统化的方式将真正原因加以防止,利用永久改善对策来避免再发。

6-2-7Verification

效果确认:

改善对策的有效性应经由数据收集作确认,资料可来自制程管制的数据、出货品质保证的数据、进料品质检验数据或与问题相关的数据,利用数据加以验证改善对策的有效性。

6-2-8Prevention

防止再发:

经确认用于永久改善之对策以避免再发之相关具体做法,可列于此作为对策实施之有效性验证,可附数据加以证明。

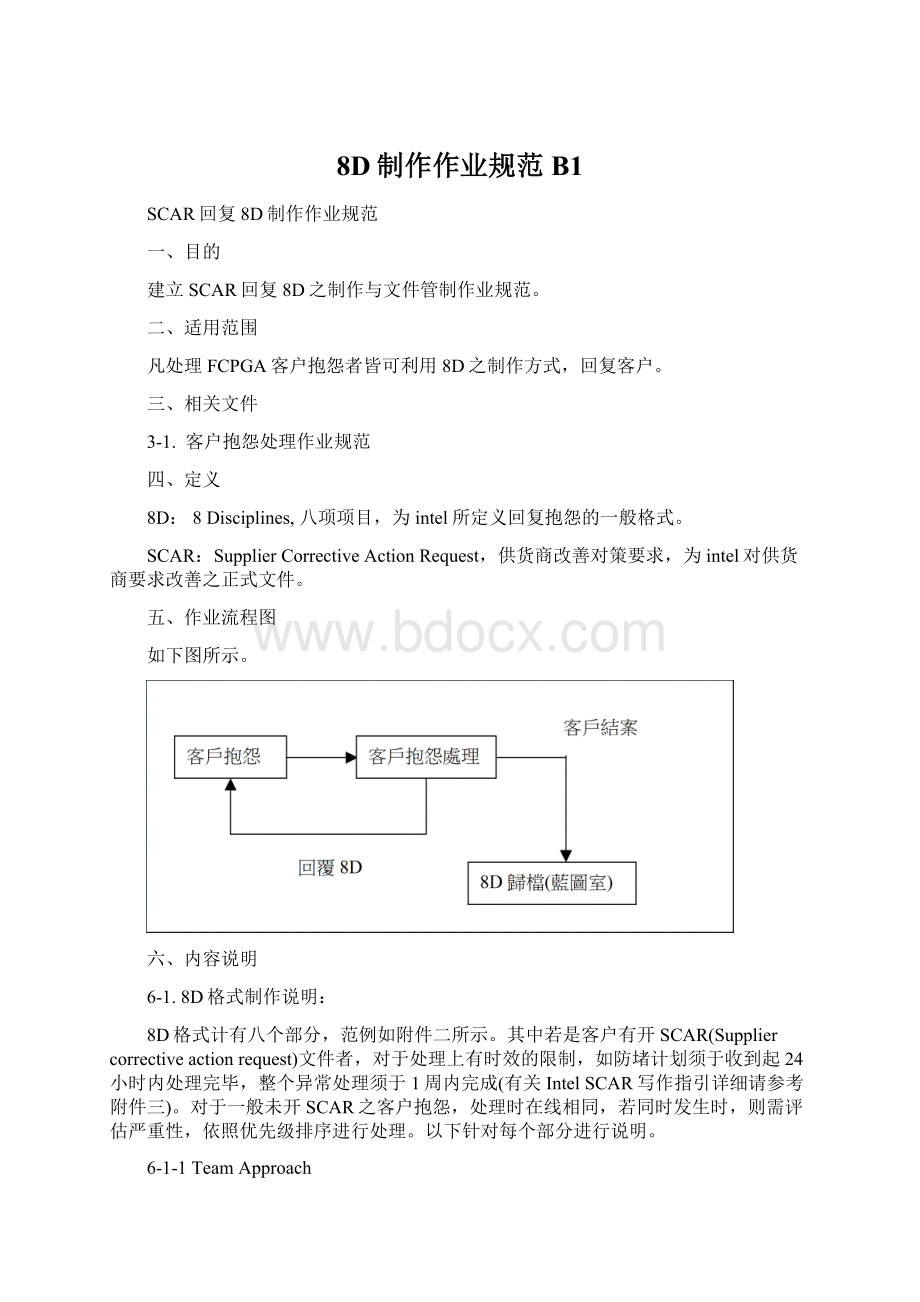

七、查核作业

响应客户之改善对策8D文件需列入文件管制,储存于蓝图室。

CQE完成8D的报告后,经客户同意结案,8D文件需附上文件签核单(如附件一),依照该流程完成文件归档。

品保工程师依照客户抱怨处理作业办法进行客户抱怨相关事务的处理。

汇整来自与客户相关之会议、改善小组或SCAR之改善对策,附制程改善工程师(JE)之改善报告提出offspec「参考offspec作业规范」并定出稽核频率及实施期间,经CCB核准后执行改善行动(CorrectiveAction)。

透过对策稽核,依照稽核频率进行稽核,并将稽核结果响应给CQE,CQE依照实施之效果提出评估报告,判定是否结案或转入厂内稽核系统「第三类稽核」继续进行改善稽核,CQE则需将稽核结果分析汇整后评估改善行动的效果,提出评估报告检讨并响应客户品质改善成果。

八、核准及施行

1.核准施行程序:

本项规范由品保部品保课负责制作,经行政系统核准后实施,修订时亦同。

2.保密措施

2-1.保密等级:

『SCAR回复8D制作作业规范』的保密等级区分,属于全厂可公开讨论,但不可泄漏于厂外人员,因此属于密级资料。

2-2.规范保管方法:

本规范经过制订、审核、核准程序后,由蓝图室负责登录于计算机,个人仅能依特定权限于终端机查阅,而且不得打印或复制。

分发给蓝图室与相关单位的规范,禁止擅自复印并列入管制文件保管。

九、其它

A.SCAR及客户抱怨处理文件分成两类:

A类:

SCAR,B类:

一般客户抱怨。

B.客户抱怨分三种等级:

A:

SCAR抱怨、B:

一般异常抱怨、C:

偶发性异常抱怨。

十、附件

附件一:

SCAR履历表编号:

.

8D文件名称:

客户抱怨处理纪录表

制订单位

制订日期

制作人

审核

会签

品保部

分发

品质工程课

核准

90单位

制作单位

使用单位

CTQ20

客户名称:

Intel

影响料号:

抱怨内容:

FCPGA板边铜burr

客户文件编号:

文件分类:

A(SCAR)

客户抱怨等级:

风险评估:

LOW

有无退货板:

退货数量:

units

其它说明:

1.客户抱怨内容说明摘要:

-发生时间:

-问题描述:

-真正原因:

-防堵措施计项。

-改善对策计项。

-结案时间:

2.响应客户对策内容:

(请条列AR内容、负责单位、预计完成时间)

文件流程:

制定单位→制定单位主管审核→90,品质工程课会签→Q00核准→90单位及使用单位存盘

管理。

本文件保存于蓝图室至履历表废止或变更。

附件二:

回复客户抱怨的8D范例:

COMPEQMANUFACTURINGCO.,LTD.

POBox100Tayuan,Taiwan,R.O.C.33803

Telephone:

(8863)386-3000

Facsimile:

(8863)385-7711

EIGHTDISCIPLINEWORKSHEETRev.:

____

Thesuppliermustsubmitthecorrectiveactionresponseinthe8-Dformatspecifiedbelow.Notethatthesectionsaredueatdifferentintervals.

Serial#

Opendate

PartNumber

A12191

05/05/00

DefectDescription

Foreignmaterialinsealedmoisturebagsandsubstrate

Requester

ChristopherChunYee

Closedate

Supplier

CompeqManufacturing.Co.,Ltd.

SupplierContact

RogerChen(ext.:

5322)

Discipline1:

TEAMAPPROACH

1.CTplantmanager:

JerryKuo.

2.Owner:

K.C.Tseng.

3.Member:

KenLee,RogerChen,SamuelPeng,ShinerHuang,JasonLin.

4.Customer:

n/a

Discipline2:

PROBLEMDESCRIPTION

Failuremode:

ForeignMaterialinthesealedmoisturebagsandonsubstrate.

Dateissuedetected:

WW19.5.

AffectedSLILot:

SLI#CT017.619~CT018.756.

AffectedCustomersite:

KM1-116K,PG-TBD,CV1-TBD,CR-n/a

Defectrate:

100%

Discipline3:

ANALYSISFINDINGS

1.Inspected100whiteplasticcoversandwhitecolorFM(aslargeas4mminlength)wasfoundfallingofffromtheboards(refertopicturebelow).The“FM”isfoundtobetheflakesofwhiteplasticcovermaterialswhichwascreatedduringthecuttingprocess.

2.Inventorystatus:

(updateWW20.1)

TotalDefectiveMaterials:

5,000uncleanboards.

Defectivematerialsshippedtocustomer:

2,900boards.

Compeqinventory:

92kpackedWIP

2,100boards

Discipline4:

COTAINMENTACTION

ContainmentAction

Owner

ECD

Status

1

Determinecleaningmethod

2

Screen&

cleanin-housematerials

-Packedunits(92k)

-Whiteplasticcover(2100boards)

ww20.5

Done

3

Plasticcovermaterialssuppliercontainment

4

Addaircleaningprocesspriortopacking

5

SentlocalreptoarrangecontainmentsupportinIntelfactory

Discipline5:

ROOTCAUSE

The“FM”isfoundtobetheflakesofwhiteplasticcovermaterials.Theresultofinvestigationshowedtheplasticcoversupplierhadaprocessexcursionwherethesteamaircleaner(afterthecuttingprocess)wasoutoforderatApril8.TheplasticcoverwithuncompletedprocesswasshippedtoCompeqwithoutnotification.Also,thereisnoIQCsystemin-place@Compeqtocheckonthisplasticcover.

Experiment

Discipline6:

CORRECTIVEACTION

CorrectiveAction

AddplasticcoverinIQClist

ww19.5

Inspectplasticcoverpriortopacking

1.Addplasticcovercheckingiteminthepackagingprocess,implementedbyWW19.5.

2.AddplasticcovercheckingiteminCompeqmaterialIQCsystem.ECD:

WW20.5.

Discipline7:

VERIFICATION

DataCollected

SampleSize

Results

Out-goingpackagingcheckpriortoshipping

153k(100%)

0FM

I

1.153kunits,shippingatWW19.6andWW20.1,werecheckedwithoutdefectfound.

2.Suppliercorrectiveactionverification:

Thenewcoming3,000unitswerecheckedwithnowhiteFMinside.

Discipline8:

PREVENTION

1.Thefirststep,utilizingIQCsystemtomonitortherawmaterial.

2.Thesecondstep,usingtherevisedpackagingprocesstodetectthenonconformingunits.

附件三:

INTELSCAR写作指引

SUPPLIERCORRECTIVEACTIONREQUEST(SCAR)INSTRUCTIONS

TheSupplierCorrectiveActionRequestformisintendedtobeinresponsetofailuresrelatedtoanyaspectofsupplierperformance,includingbutnotlimitedtoproductdeliveryorperformanceandthesupplier'

smanagementsystemperformance.Itsmainobjectiveistosystematicallydocumenteffortsbythesuppliertoaccomplishthefollowingthingseitherinadvanceoforfollowingtheoccurrenceofaproblem.

Recoverthecommitmentorschedulefortheitemeffected.

Containtheproblembyidentifyingtheotheritemseffectedbytheproblemandputtinginplaceplansmaintainingtheiroriginalcommitmentsorperformance.

SystematicallydevelopaRootCauseSystemFixfortheproblemsuchthatthesupplier'

ssystemwillnotallowtheproblemtoreoccur.

FollowuponcorrectiveactionswithpermanentSpecificationand/orContractChangeNoticesthatbringexpectationsintoalignment.

SCARPROCESS

1.IntelProcedures:

1.1WhenaproblemoccurstheIntelMaterialQualityEngineer(MQE)orCommoditySpecialist(CS)willinitiateaSupplierCorrectiveActionRequest(SCAR)forthecommodityteam.

1.2TheIntelMQE/CSwilldocumentthedetailsregardingthediscrepantmaterial,attachsupportingdocumentation,andforwardtheSCARtothesupplierusingtheIntelSCARtool.

1.3TheSCARpackagewillthenbeelectronicallymailedtothesupplierwithcopiessenttotheappropriateIntelpersonnelandtheSupplier'

scustomermanagementteam.

1.4ThesupplierwillacknowledgereceiptoftheSCARandwillincludeintheacknowledgmentcommitdatesfordeliverytoInteloftheContainmentPlanandtheRootCause/CorrectiveActionPlan.

2.SupplierAcknowledgmentresponse:

2.1.ThesuppliershouldacknowledgetheSCARwithin24hoursofreceiptofthedocument.

3.SupplierRecoveryandContainmentanalysisandplan:

3.1TheanalysisandplanmustbereceivedfromthesupplierwithinthetimerequiredbytheIntelcommodityteaminthosecaseswherecurrentorfutureunitsorshipmentscanbeaffected.

3.2Inthecaseofa"

postmortem"

typeofsituationwheretheSCARisissuedafterthefact,thesupplierrecoveryandcontainmentactivitiescanbedocumentedwiththe"

RootCause"

response.

4.SupplierRootCause/CorrectiveActionPlan:

4.1TheplanmustbedeliveredsupplierwithinthetimerequiredbytheIntelcommodityteamfromthereceiptoftheSCAR.

4.2Ifanextensionisneeded,thesuppliermustnotifytheIntelCommodityManagerinadvanceoftherequiredperiodandstillrespondwithintherequiredperiod

4.3Extensionsmustbeaccompaniedbythefollowing:

∙Preliminaryrootcause/correctiveaction

∙Scheduleforcompletionofthe"

final"

rootcause/correctiveaction

∙Newdateatwhichtimethe"

rootcauseandcorrectiveactionplanwillbedocumentedtotheIntelMQE/CS.

4.4Thesuppliermustincludethefollowingwiththerootcause/correctiveactionresponse:

∙Supportingdocumentation(e.g.processflowchartchanges,specificationdrafts,reviseddocumentation,etc.)toverifytheapproachtakenanddocumentthechangesmadesuchthatIntelwillhaveacompleteunderstandingoftheproblemandactions.

∙Supportingorimplementationdatathatverifiestheeffectivenessofthesystemfix.

5.IfthereareanyrecommendedcorrectiveactionstobetakenbyIntelasaresultoftherootcause/correctiveactionbythesupplier,theyshouldbenotedbythesupplierintheirreportandtheywillbetakenintoconsiderationbytheappropriatecommodityteam.

6.Ifthesuppliercorrectiveactionisacceptable,theSCARwillbeclosed.

7.ContestedSCARs

7.1IfthesuppliercorrectiveactiondoesnotmeetIntel'

srequirements,aformalcommunicationshallbesenttothesupplier'

smanagementindicatingthattheSCARresponseisunsatisfactory.

7.2Thesuppliermustthenresubmitarevisedcorrectiveactionplantoarrive

- 配套讲稿:

如PPT文件的首页显示word图标,表示该PPT已包含配套word讲稿。双击word图标可打开word文档。

- 特殊限制:

部分文档作品中含有的国旗、国徽等图片,仅作为作品整体效果示例展示,禁止商用。设计者仅对作品中独创性部分享有著作权。

- 关 键 词:

- 制作 作业 规范 B1

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

冰豆网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

转基因粮食的危害资料摘编Word下载.docx

转基因粮食的危害资料摘编Word下载.docx